4

to the fan casing to facilitate work on

the terminal box (fig. 6).

3 Disconnect the motor cable in the

terminal box and loosen the internal

cable connector (fig. 7, pos. 1) at the

separation from the pressure

chamber. Push the cable fully into the

pressure chamber.

4 Prepare support of the motor

arrangement, e.g., with a lift, in order

to lift it as short as possible and

preferably straight down.

5 Loosen the motor arrangement (eight

M8x16) (fig. 8, pos. 1) from the fan

casing and take it down.

The arrangement requires two people

to take down safely. Make sure to pull

the motor cable completely free of the

fan casing.

6 Leave the wire guard affixed to the

inlet nozzle (fig. 8, pos. 2).

7 Remove the impeller by removing the

motor shaft screw (fig. 8, pos. 3).

8 Disconnect the motor from the inlet

nozzle. It is attached with eight 12x20

screws (fig. 8, pos. 4).

9 Slide the steel tube off the motor cable.

The motor is now ready for service. Refer

to the motor supplier’s instructions for

service.

7.7 Assembly of motor

Lubricate bolts with grease, before

screwing them in during re-assembly.

Assembly procedure

1 Slide the steel tube onto the cables for

the new motor.

2 Affix the motor to the inlet nozzle

with the eight 12x20 screws (fig. 8,

pos. 4).

3 Install the impeller on the inlet nozzle

and attach to motor shaft.

4 If the wire guard has been removed,

then this is affixed to the inlet nozzle

with four blind rivets 3.2x10 of

stainless steel grade A2 (fig. 8, pos. 2).

5 Support and place the motor

arrangement in the fan casing. Make

sure to pull the motor cable along the

same route as was done from the

factory.

The arrangement is attached with

eight M8x16 screws (fig. 8, pos. 1).

6 Roll the motor cable up into the

terminal box room before tightening

the connector at the separation from

the pressure chamber.

7 Connect the motor cable in the

terminal box and install it and the

cover (fig. 6).

8 Tighten the external motor cable

connector.

9 Connect the power supply for the fan

and follow the procedure for startup

in section “6.2 Start procedure”.

7.8 Troubleshooting

The following are possible causes of

breakdowns and failures.

Poor performance

• The inlet or the outlet side of the fan

is blocked.

• Motor defect

• Motor disconnected

• Faulty electrical connection

• Wrong direction of rotation

Noise/vibrations

• Faulty bearings in motor

• Impeller imbalance

• Wear/damage to impeller

• Loose screws/components

• Fan operates in stall condition, which

may lead to damage. Correct faults -

see “Poor performance”.

• Aged or ruptured vibration dampers

8. Inspection and test

It is recommended to test and inspect the

CGF fans at regular intervals with regard

to operability and operating conditions.

Extent of inspection

• Measure power consumption at high

and low speeds

• Check torques for fixing bolts and

correct if necessary

• Vibration measurement on fan casing

(next to motor)

• Visual inspection of impeller, fan

casing, vibration dampers, and

electrical connection

• Cleaning

– inside with a wet cloth, pressurised

air or vacuum cleaning

– outside with water - avoid water in

the electrical systems

Enter all values and observations in a

log.

Figure 7.

Loosen internal connector

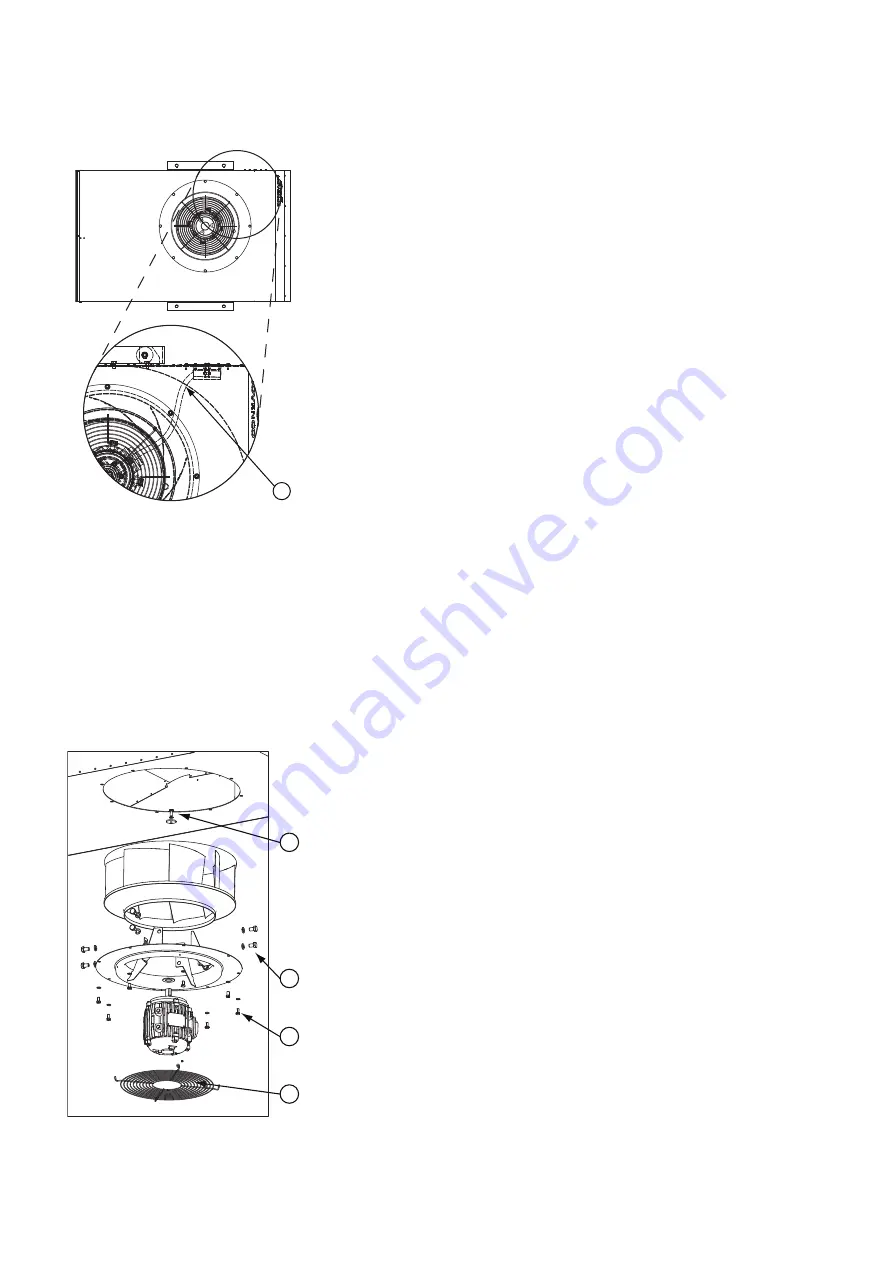

Figure 8.

Disassembly of motor

1

2

1

4

3