COMPACT 75

COMPACT 75

Operator’s manual for drilling machine

- 25 -

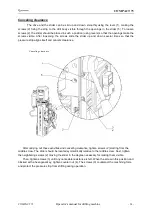

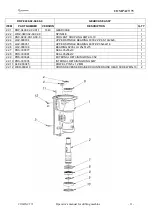

Replacement of motor brushes

For the

COMPACT 75

drill, the condition of the carbon brushes should be monitored every 100

working hours.

Replacement of motor brushes should take place when the machine is turned off and

the power cable is disconnected from the power grid!

1.

Unscrew 4 M5x40 engine cover screws (1), using a 6

-kt s=4 wrench.

2. Carefully

take off the engine cover (3). Remember that it is connected with the motor by a

grounding lead (4).

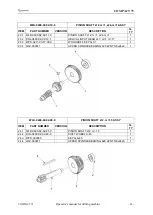

3.

Take off the motor brushes from the connector (6) using the flat ending (5) of the lead. The ending

has a safeguard against its sliding down – first, press the protruding element at the middle of the

ending, then carefully slide off the ending from the connector.

4.

Push aside the spring arm (7) pressing down the brush and rest it on the surface of the brush

holder (8) and remove the brush (9).

5. Inspect brush length – if the length is less than 5 mm, the brush should be replaced with an

original brush.

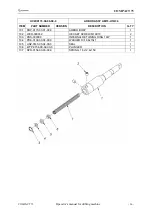

6. Carry out all actions in reverse, in order to install the engine.

After replacement, new brushes should be grinded in for about 20 minutes on idle gear.

Replacement of engine brushes is possible without removing the drive from the drill.