COMPACT 75

COMPACT 75

Operator’s manual for drilling machine

- 13 -

Preparation for cutting

1. Place the drilling machine on the working surface.

2. Secure the milling cutter firmly and accurately in the spindle socket

3. Fill the bottle of the cooling system with the cutting fluid.

4. For drill and milling cutter cooling during drilling it is recommended to use cutting fluids available

on the market in the condensed form. It is also possible to use emulsion formed by mixing water

and drilling oil.

Using pure water as a cutting fluid is not allowed.

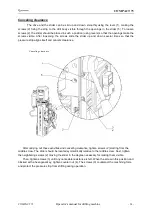

5. Check operation of the cooling system. To do this loosen bottle nut, set the knob of the small valve

to position ”ON” to initially bend the pilot placed inside the milling cutter by lowering the drive on its

guides. The fluid will fill the system and after short period it will start flowing out from the inside of

the drill.

CAUTION: Cooling system works according to gravitation. Due to

this in another drilling position than vertical the cooling liquid must be

provided manually.

6. Define the direction of the spindle rotation.

7. Set proper rotational speed according to the type of the tool and working material.

8. Connect the drilling machine to electric network according to

9.

Set the axis of the spindle right above drilling point (in the case of

milling cutter the end of the pilot

helps with alignment).

10. Turn the mounting of the electromagnetic base on.

To be sure check if electromagnetic base is properly secured, in the case of horizontal

works, works on ceilings and on heights secure it by using chain or safety belt.

Preparation for tapping

1.

Using a MT3 wedge (included in a set) put the milling head holder (AMT3

-U-19/3-3, included in

the set) out of the drilling machine spindle.

2. Mount the tap socket with 1- or 2-axis compensation into the spind

le (not included in the set).

3. Choose the right socket adapter to match tipping diameter. Mount tap no. 1 into the adapter and

place it in the compensation socket.

4. In the case of using taps with conical handle, mount it directly into the spindle or by using reducer

with MT3 cone.