OPM 260 en-GB

41

©

Scania CV AB 2021, Sweden

Cooling system

Risk of freezing

IMPORTANT!

The engine should not be subjected to heavy

loads when ice starts to build up in the cooling

system.

As the coolant starts to freeze, the water in the

coolant starts to crystallise and the percentage of

ethylene glycol in the coolant therefore rises. If

freezing produces a great increase in the amount

of ice, circulation problems could arise. There is

no risk of damage by freezing if the content of

Scania antifreeze and corrosion protection, or an

equivalent mixture of a similar product, is at

least 35% by volume.

Minimal ice formation in the coolant sometimes

causes disruptions without any risk of damage.

For example, the auxiliary heater may not work

for up to one hour after the engine has been start

-

ed.

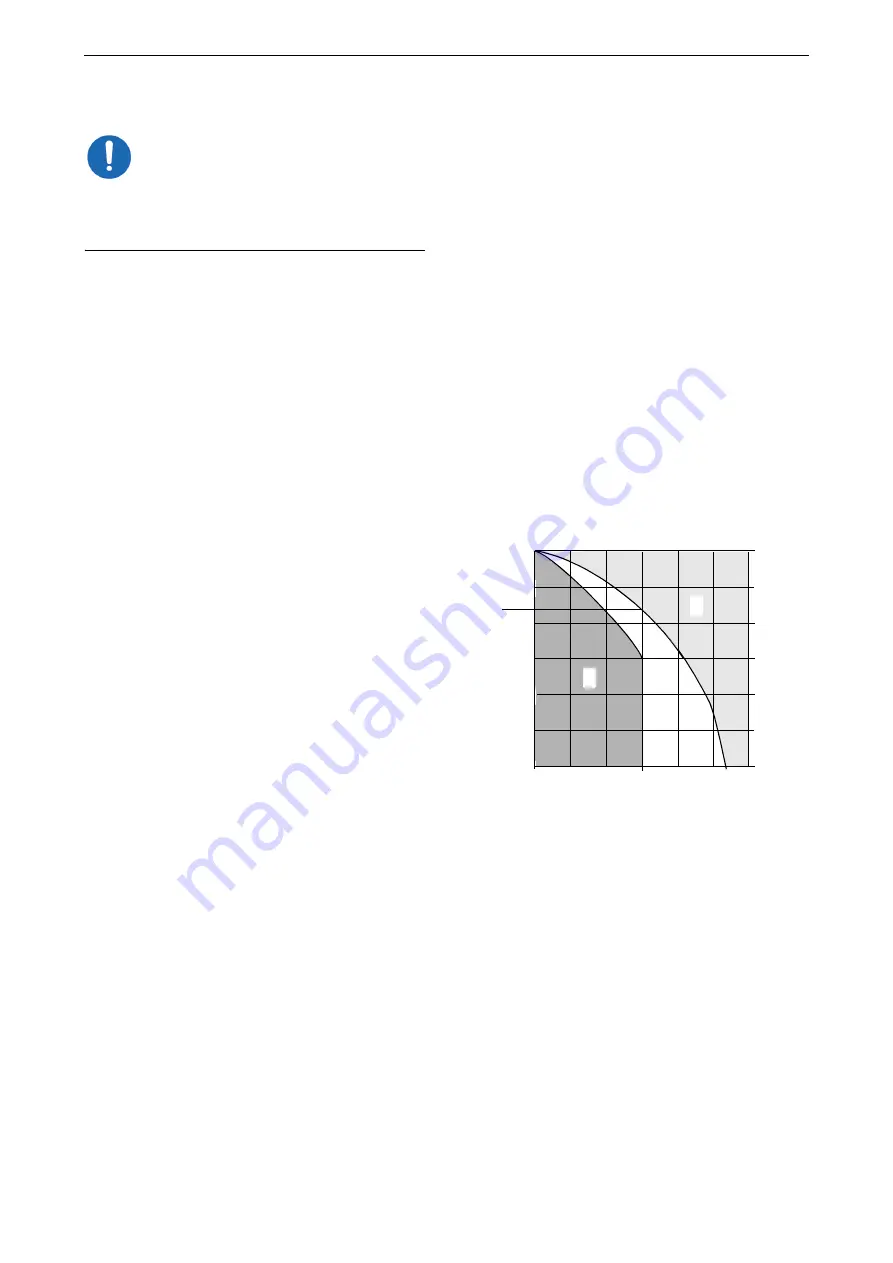

The chart depicts coolant properties at different

percentages of antifreeze and corrosion protec

-

tion concentration by volume.

The following example shows coolant properties

with 30% by volume of antifreeze and corrosion

protection:

•

Ice slush starts to form at -16°C (3°F).

•

At -30°C (-22°F), there is a risk of disruptions

in the cooling system.

•

There is no risk of damage by freezing with a

minimum antifreeze and corrosion protection

content of 35% by volume.

Example: If the temperature is -16°C (3°F), there

is a risk of damage by freezing if the percentage

of antifreeze and corrosion protection is 20% by

volume. At 30% antifreeze and corrosion protec

-

tion by volume the coolant will not contain any

ice.

Curve A: Ice formation starts (ice slush)

Curve B: Damage by freezing

Zone 1: Safe zone

Zone 2: Disruptions may occur (ice slush)

Zone 3: Risk of damage by freezing

10

20

30

40

50

60%

o

C

o

C

o

C

o

C

o

C

o

C

o

C

-10

-20

-30

-40

-50

-60

-16

3

2

1

A

B

1

2

1

1

3

4