Sauter GmbH

Tieringerstr. 11-15

D-72336 Balingen

E-Mail: [email protected]

Tel: +49-[0]7433- 9976-174

Fax: +49-[0]7433-9976-285

Internet: www. sauter.eu

Instruction Manual

TU_US

TU_US-BA-e-1110

11

will be minimized by calibrating each test piece

individually.

An additional important consideration is , that any included

air gaps or air pockets will cause an early reflection of the

ultrasound beam. This will be noticed as a sudden

decrease in thickness in an otherwise regular surface.

While this may impede accurate measurement of the total

material thickness, it does positively indicate any air gaps

in the laminate.

Suitability of materials

Ultrasonic thickness measurement relies on passing a

sound wave through the material being measured. Not all

materials are suited to transmitting sound. Ultrasonic

thickness measurement is practically found in a wide

variety of materials including metals, plastic and glass.

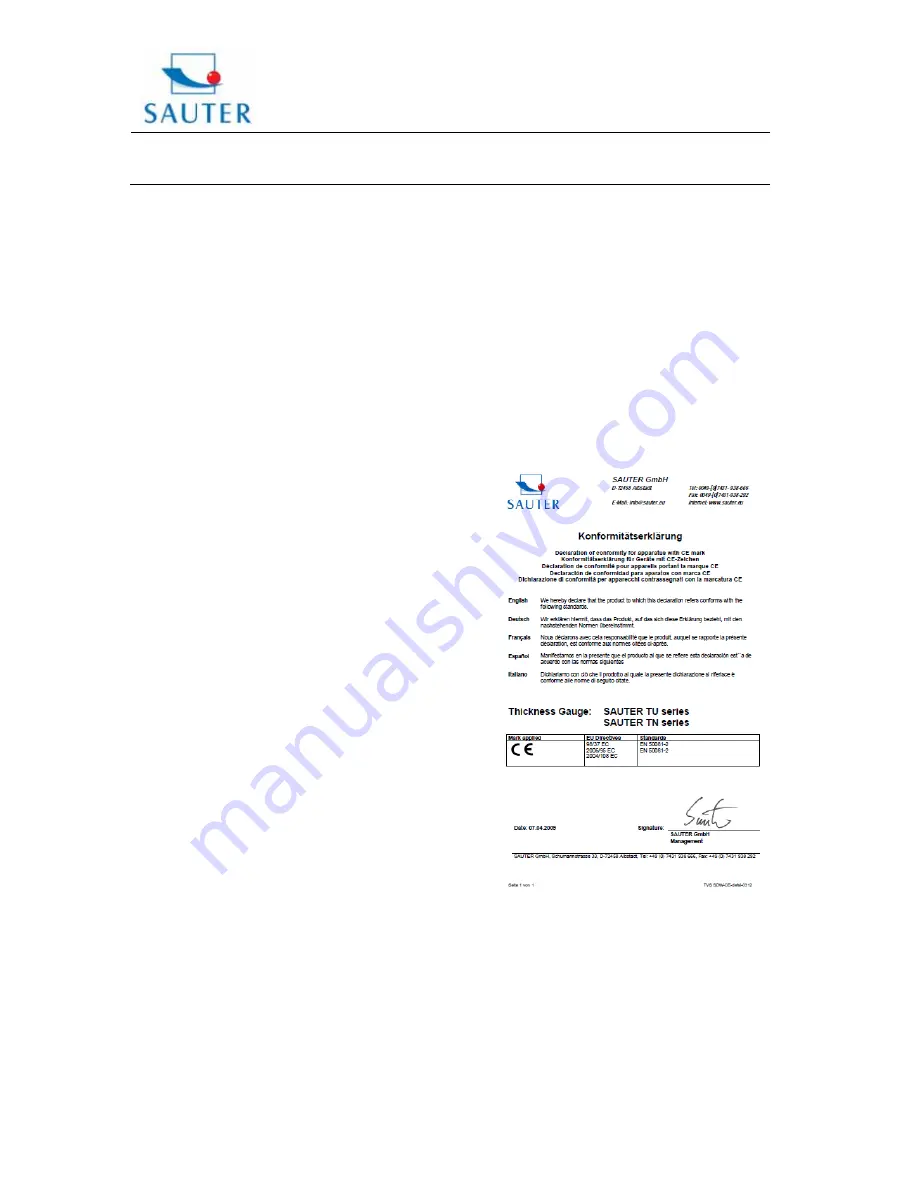

7. Declaration of conformity

Materials which are difficult include some cast materials,

concrete, wood , fibreglass and some rubber.

Coupling medium

Every ultrasonic application requires some medium to

couple the sound from the transducer to the tested

material. Typically, a high viscosity liquid is used as the

medium. The sound used in ultrasonic thickness

measurement doesn’t travel through air efficiently.

A wide variety of coupling mediums may be used.

Propylene glycol is suitable for mostly all applications. In

difficult applications, where a maximum transfer of sound

energy is required, glycerine is recommended. However,

on some metals glycerine may promote corrosion by

means of water absorption, which is undesirable.

Other suitable coupling medium for measurements at

normal temperatures may include water, various oils and

greases, gels and silicone fluids. Measurements at

elevated temperatures will require specially formulated

high temperature coupling medium.

Inherent in ultrasonic thickness measurement is the

possibility that the instrument will use the second rather

than the first echo from the back surface of the material

being measured while being in standard pulse-echo mode.

This may result in a thickness reading that is TWICE what

it should be.

The responsibility of a proper use of the instrument and the

recognition of these types of phenomenon solely rest with

the user of the instrument.