-7-

Electrical Adjustments

1. Receive the 1 line black/white pattern computer signal

with

computer1 [rGB]

mode.

. Enter the service mode.

3. Project only green light component to the screen.

4. Select group no. “

100

”, item no. “

127

” and change data

value to obtain the minimum flicker on the screen.

5. Project only red light component to the screen.

6. Select item no. “

128

” and change data value to obtain

the minimum flicker on the screen.

7. Project only blue light component to the screen.

8. Select item no. “

129

and change data value to obtain

the minimum flicker on the screen.

m

Common Center adjustment

1. Receive the 16-step gray scale computer signal with

computer1 [rGB]

mode.

. Enter the service mode, select group no. “

100

” item

no. “

7

” (Red) or “

8

” (Blue), and change Data values

respectively to make a proper white balance.

Confirm that the same white balance is obtained in video

and computer input.

.

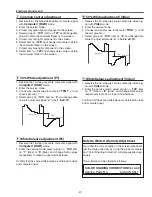

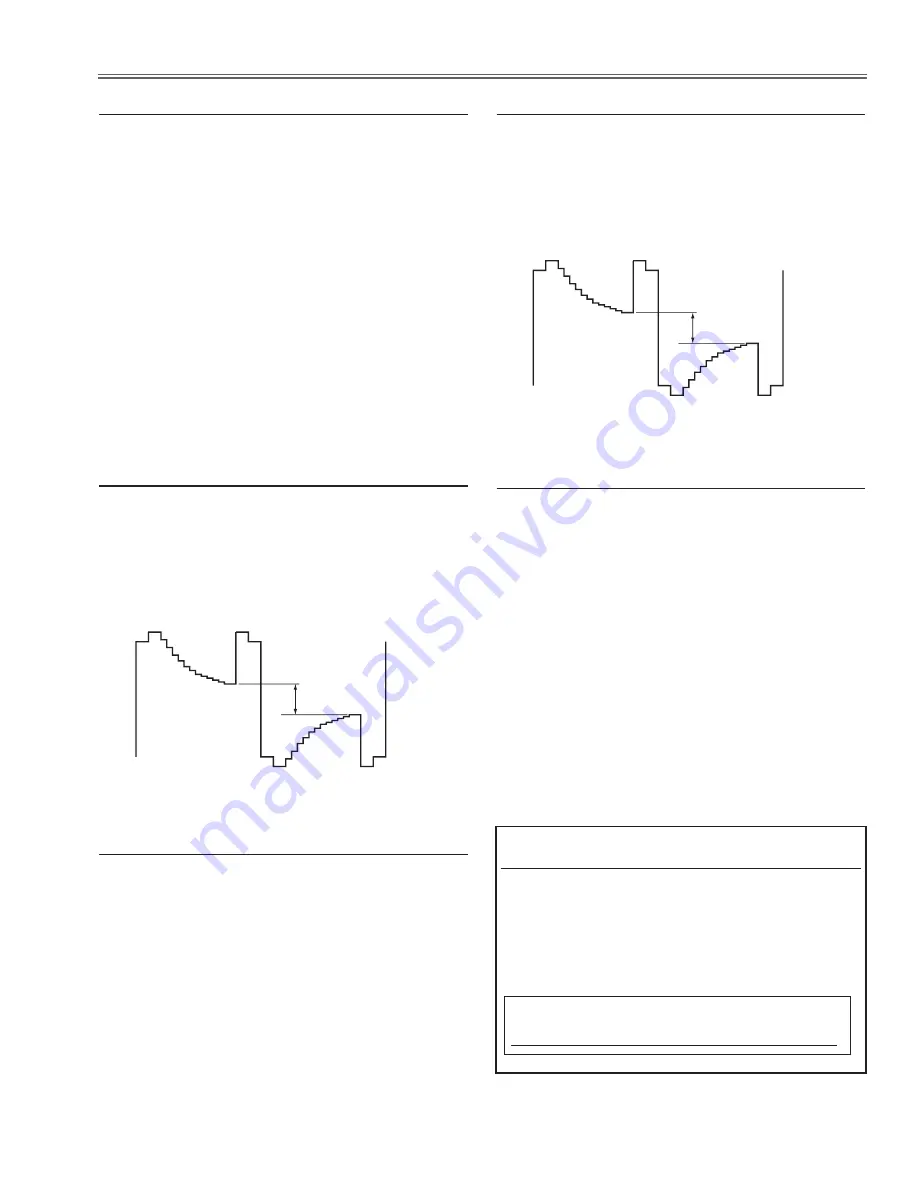

White Balance adjustment [PC]

1. Receive the 16-step grey scale computer signal with

computer1 [rGB]

mode.

. Enter the service mode.

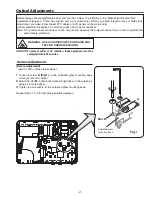

3. Connect an oscilloscope to test point “

tPG1

” (+) and

chassis ground (-).

4. Select group no. “

100

”, item no. “

6

” and change data

value to adjust amplitude “

a

” to be

1.6 ±0.1V

.

(a)

white level

white level

,

50% White adjustment [PC]

1. Receive the 16-step grey scale composite video sig-

nal with

Video

mode.

. Enter the service mode.

3. Connect an oscilloscope to test point “

tPG1

” (+) and

chassis ground (-).

4. Select group no. “

100

”, item no. “

6

” and change data

value to adjust amplitude “

a

” to be

2.2 ±0.1V

.

(a)

white level

white level

⁄0

50% White adjustment [Video]

1. Receive the 16-step grey scale composite video sig-

nal with

Video

mode.

. Enter the service mode, select group no. “

100

” item

no. “

7

” (Red) or “

8

” (Blue), and change Data values

respectively to make a proper white balance.

Confirm that the same white balance is obtained in video

and computer input.

⁄1

White Balance adjustment [Video]

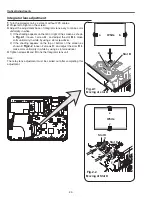

Note On White Uniformity Adjustment

If you find the color shading on the screen, please ad-

just the white uniformity by using the proper computer

and “Color Shading Correction” software supplied sep-

arately.

The software can be ordered as follows;

coLor SHAdING correctIoN Ver. 4.00

Service Parts No.

645 075 9611

Summary of Contents for 1 122 356 20

Page 18: ... 18 Optical Parts Disassembly m Optical Unit Top removal M3x8 x5 Optical top Fig 7 ...

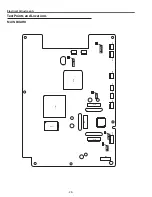

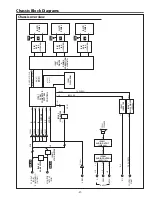

Page 53: ... 53 IC Block Diagrams FA5502 P F Control IC621 L3E6100D D A S H LCD Driver IC501 IC531 IC561 ...

Page 54: ... 54 IC Block Diagrams L3E07072 LCD Driver Gamma Correction IC401 M62393 DAC IC3531 ...

Page 55: ... 55 IC Block Diagrams NJW1141 Audio Control IC5001 ...

Page 81: ...KR6 XW55A00 KP6 XW50A00 81 Mechanical Parts List ...

Page 82: ... KR6AD Jun 2007 DC 350 Printed in Japan SANYO Electric Co Ltd ...