Page 12

LCD Menu keys

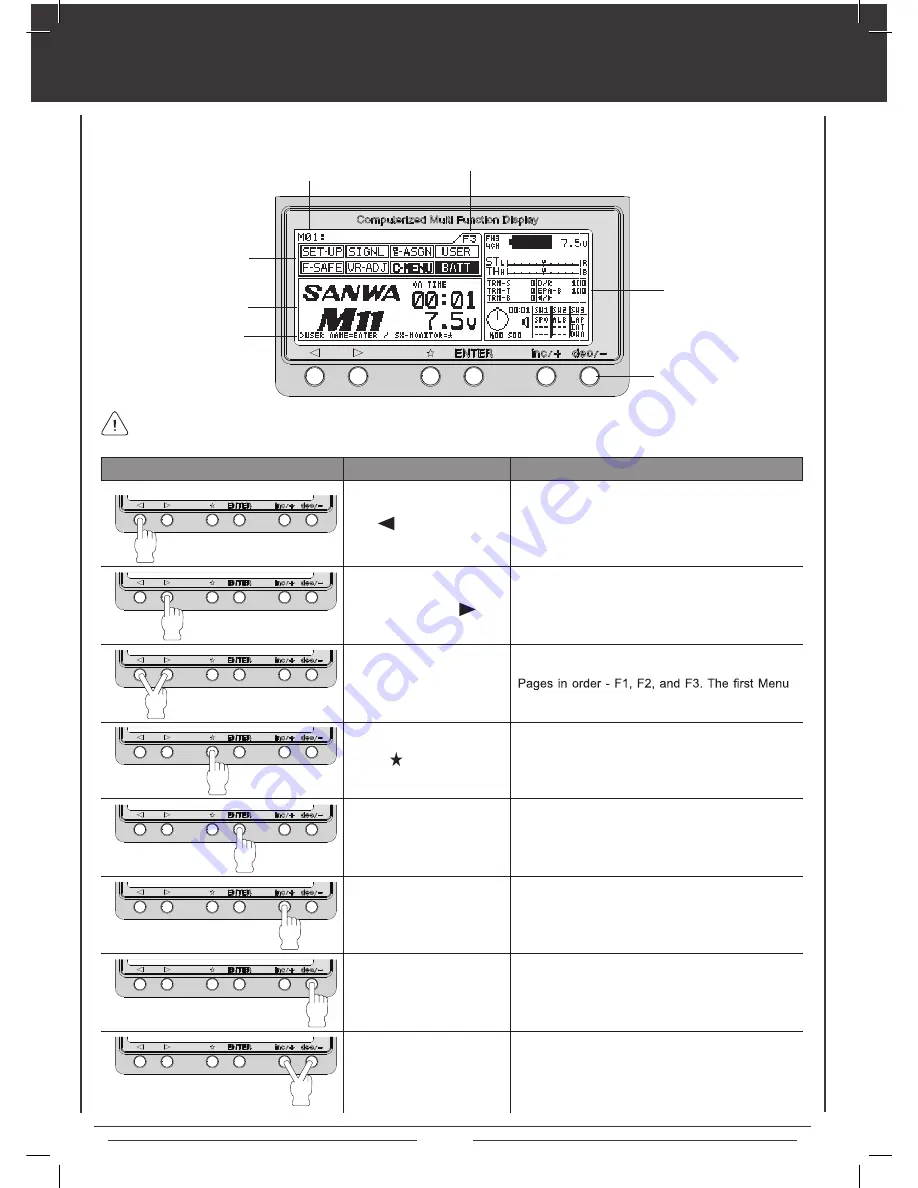

The SANWA M11X FHSS-3 2.4GHz transmitter features six menu keys for menu operation. This section summarizes the functions

of each of the 6 menu keys in addition to describing the main areas of the LCD Display.

Model Number

Menu Function

Programming

Window

Help Display

Area

Key Pad

Information

Window

Function Page

Moves the Menu Function cursor left (backward)

to the previous menu function. Turning the Dial

Knob counter-clockwise will move the Menu

Function cursor left, too.

Moves the Menu Function cursor right (forward)

to the next menu function. Turning the Dial Knob

clockwise will move the Menu Function cursor

right, too.

Function Page Select

Key Sequence

Pressing both keys will scroll through the Function

Function will be highlighted on each page.

KEY

NAME

FUNCTION

Moves the Cursor backward in the Programming

Window. Also used in the Help Display Area and

to display the Information Window.

Enter Key

Moves the Cursor forward in the Programming

Window. Also used in the Help Display Area.

INC/+ Key (Increase)

Increases number values in the Programming

Window. Also scrolls up a Selection List.

DEC/- Key (Decrease)

Decreases number values in the Programming

Window. Also scrolls down a Selection List.

INC/+ and DEC/-

Key Sequence (Reset)

Pressing both keys together will Reset the selection

to the Factory Default Setting.

A plastic cover is included that snaps over the LCD display and key pad to protect it during travel or storage.

Scroll Key

Function Key

Function Key

Summary of Contents for M11X

Page 1: ...OPERATING MANUAL 670A12978A ...

Page 67: ...Page 67 notes ...