Sanosil Q-Jet Compact

14

5.

Maintenance

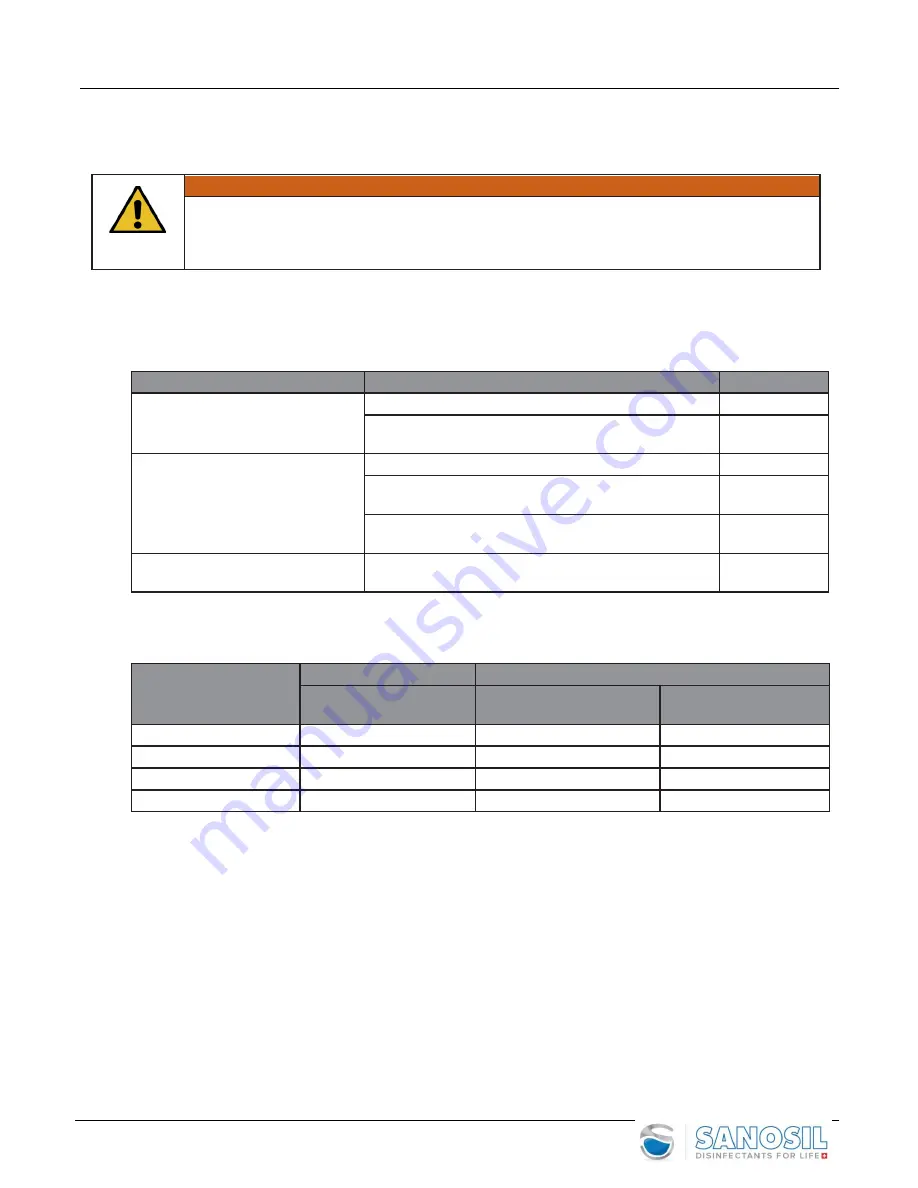

WARNING

Risk of injury!

Do always switch off the device and disconnect the power supply cord/plug before starting any cleaning or

maintenance works! Maintenance works can only be carried out through well-trained personnel or

professional electricians. Observe all safety indications stated above, in chapter 2.

5.1

Regular visual check and Maintenance

Do not tip the device on its side at any time unless completely empty and dry.

Group/Component

Operation

Cycle

Air circuit /

Device structure

Airfilter:

clean if dirty or replace if damaged

monthly

Structure:

visual check of the state

(dents, breakages of parts)

monthly

Device in general

Visual control:

Checking operationality

daily

Components:

status of device’s components

(integrity of components, fluid loss, sealings, caps)

monthly

Documentation:

Verification that all documentation for the

device is updated and available

yearly

Hydraulic Circuit

Nozzle:

Visual status check (cracks, points of rupture, brui-

sing, occlusions, deposits)

daily

5.2

Extraordinary Maintenance

Intervention-Type

Inspection

Checking / Verification

Visual Inspection

Leakage and Seals

Flow and Internal Tensions

A

X

X

X

B

X

X

X

C

X

X

X

D

X

X

(A)

Inspection / Check after an intervention or assistance involving replacements or repairs of components.

(B)

Inspection / Check after device has not been used for a longer period (6-12 months) or after it has been on

work for 2 years.

(C)

Inspection / Check after change of person responsible for the device.

(D)

Inspection / check to be made yearly.