15

Run the machine where air can be supplied in a stable condition.

Use after-cooler or similar equipment to supply clean air at all times.

Operation Procedures

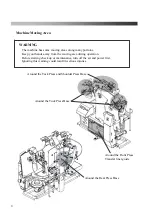

Provide Air

Check whether air pressure is set at the required

level for main regulator and other regulators as

below.

①

Main Regulator

・・・

0.6MPa

②

Regulator (for Sleeve Down)

・・・

0.25MPa

③

Regulator (for Slide / Sleeve Up)

・・・

0.3MPa

Low air pressure can cause a malfunction. If the pressure does not reach its standard

level, set the air pressure properly following the procedure below.

Check Point

Check compressor if the main air pressure does not reach 0.6MPa even after the

above adjustment

Follow the procedure for proper operation.

Improper operation can cause mechanical failure or injury to operators.

■

How to adjust air pressure

1.

Pull the adjustment knob up.

2.

Turn the knob to adjust air pressure

Clockwise

→

Pressure will increase

Counterclockwise

→

Pressure will decrease

3.

Push the knob down.

②

①

Attention!

③

Caution

Summary of Contents for LP-570E-V2

Page 54: ...54 Motor Operation Diagram 1 Motor Operation Diagram REV 4...

Page 56: ...56 Air Piping 1 2 Air Piping 1 REV 3 3DLP570E V2 052 2...

Page 58: ...58 Air Piping 2 3 Air Piping 2 REV 3 3DLP550J V2 053 6...

Page 60: ...60 Air Piping 3 4 Air Piping 3 REV 3 3DLP550J V2 054 6...

Page 62: ...62 Steam Piping 5 Steam Piping REV 3 3DLP570E V2 055 1...

Page 64: ...64 Control Box Switch Diagram 6 Control Box Switch Diagram REV 3 3DLP550J V2 056 6...

Page 66: ...66 Cover Diagram 7 Cover Diagram REV 3 3DLP570E V2 057 3...

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ...LP 570E V2X Rev 6 2019 6 1 2 B...