9

.

Maintenance

9- 1

.

Maintenance

Periodically clean the printer to maintain the printing quality and avoid failures. It is recommended

to maintain the printer every 6 months or 1 million lines of printing.

(

1

)

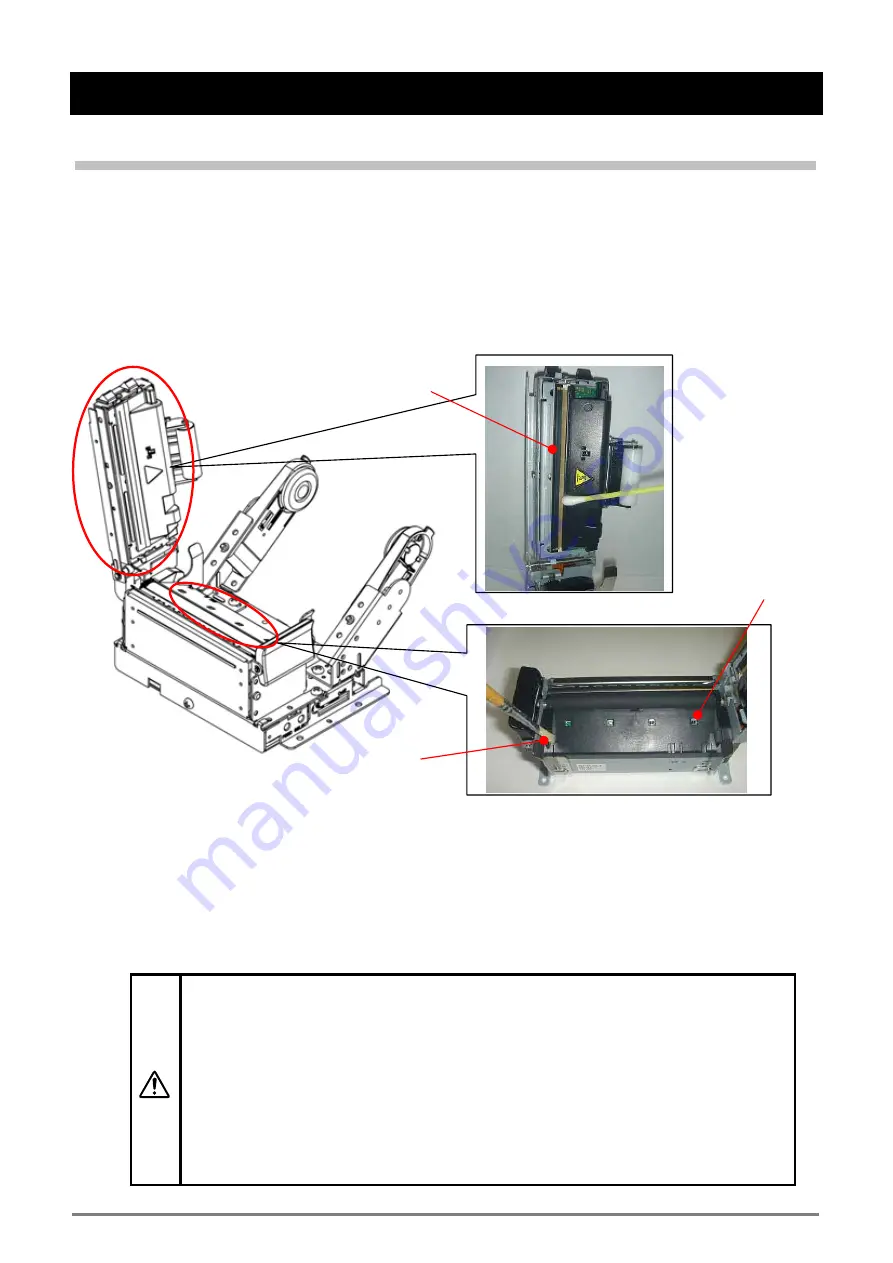

Print head

When cleaning the thermal dot line on the print head, use a cotton swab with alcohol

(ethanol, methanol or Isopropyl alcohol) and wipe off stains and dust.

49

SK1-211/311

Paper cover

sensor

Thermal dot line

Paper empty

sensor

(

2

)

Platen roller

When cleaning the platen roller, use a dry soft cloth and wipe off the stain with rotating

the roller.

(

3

)

Sensor and peripherals

Clean the stain, dust and paper powder on the paper empty sensor and paper cover

sensor.

・

Prior to maintenance work, be sure to turn OFF the printer.

・

Avoid cleaning the print head immediately because the print head is hot.

Start maintenance work after the thermal head becomes cool.

・

Do not touch the print head with fingers directly. It may cause damage by

electrostatic discharge and contamination.

・

Do not touch the thermal head dot line with bare hands or metal objects.

・

Do not use volatile chemical agents, such as thinner and benzene.

・

Do not get moisture or spill liquids inside of the printer.

・

Turn ON the printer only after alcohol is completely dried.

Summary of Contents for SK1-211

Page 1: ...Technical Guide KIOSK PRINTER SK1 211 SK1 311 Rev1 1E SK1 211 311...

Page 25: ...3 7 Dimensions External dimensions Unit mm SK1 311 model SK1 211 311...

Page 26: ...SK1 211 311...

Page 27: ...SK1 211 model SK1 211 311...

Page 28: ...SK1 311 with paper 83mm 120mm SK1 211 311...

Page 54: ...10 2 Data code table PC437 SK1 211 311...

Page 55: ...KATAKANA SK1 211 311...

Page 56: ...PC850 SK1 211 311...