6

CAUTION - Improper alignment of engine and frame

mounts may cause abnormal stresses resulting in

damage to crankcases or other parts.

2. Test-fit instructions for Twin Cam style cases

with Evo Style motor mounts.

1. Assemble case halves using case bolts.

Tighten to snug. Torquing bolts to final

specification is not necessary.

2. Clean frame engine mounts and carefully

remove any irregularities from mounting

surfaces. Also inspect crankcase mounting

bosses for burrs.

3. Position case assembly in frame.

4.

Install engine mounting bolts in motor mounts,

and check clearance between mounting

bosses on cases and frame and any other

areas where frame and cases may contact

each other. Bolts may be difficult to install if

contact is severe.

5. If cases contact frame, remove them and

relieve just enough material in offending area

to provide clearance.

6. Place cases in frame, install one rear mounting

bolt and snug nut.

7. Measure gap between crankcase mounting

bosses and frame motor mounts with feeler

gauge to determine if shimming is required.

8.

If gap exists, fabricate shim just thick enough

to fill gap

9. Install opposite corner shim and mounting bolt

and nut, and tighten identical to other bolt.

10. Check other corners with feeler gauge to

confirm thickness required is same as before.

If not, determine cause and correct.

NOTE - S&S Twin Cam style crankcase installation in

Evolution style motorcycle frame is essentially the same as

stock, although additional clearancing and shimming may

occasionally be required. When this style of case is solid

mounted instead of rubber mounted, additional care must

be taken in installing the case. Main areas of concern are

between cases and frame motor mounts. Checking

clearance around and between case mounting bosses and

frame is necessary to insure that crankcase rests squarely

on motor mount pad and no stress is applied to crankcases

when mounting bolts are tightened. Shimming may be

required to compensate for variances between frames.

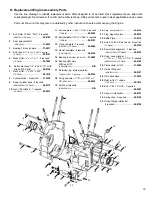

E. Engine Assembly

NOTES:

●

S&S supplies Torco Engine Assembly Lube with each

Engine. It should be used as specified in following

instructions. While other brands of assembly lube are

acceptable, other lubricants are not. In no instance should

an aerosol lubricant be substituted for assembly lube.

●

While S&S has made every effort to insure that parts are

correct, it is the engine builder’s responsibility to confirm fit

and finish of all parts provided with Engines prior to

assembly. Parts are deburred at S&S and usually require

no further preparation, but must also be inspected by

installer. Individual parts should not be removed from

protective plastic wrappers until needed. After removal

from plastic, it is imperative that parts be thoroughly

cleaned and dried, preferably with compressed air. When

present, rust preventative must be completely removed.

Additionally, gaskets must be closely inspected for particles

that could become dislodged and damage engine. If

assembly of Engine must be interrupted, seal openings and

cover engine with plastic to protect from destructive

contaminants.

Picture E2

Picture E1