H. Fuel system installation and tuning

NOTES - S&S Engine assemblies are available with either

carbureted or fuel injected systems.

Assembled Engines are shipped with the

carburetor or fuel injection system installed. Refer to

the included instructions for operation and tuning .

Unassembled Engines are shipped with the fuel

system packaged separately. Refer to the included

instructions for installation and tuning .

1. Install fuel system.

1.

Engine asemblies supplied with Super “G”

carburetors, refer to included instruction Sheet

#51-1012.

2. Engine assemblies supplied with Super “D”

carburetors,refer to included Special

Application Racing Carburetor Supplement for

additional information.

3. Engine assemblies supplied with fuel injection,

refer to included Induction System instruction

Sheet

2. Re-install and connect fuel tank.

1. Refer to appropriate service manual. Inspect

fuel lines and clamps - replace as necessary.

2. Check fuel line connections and routing. Avoid

hot surfaces. Make certain that the protective

cover has been placed over fuel line, and that

it is clear from sharp edges and abrasive

surfaces.

3. Fill the fuel tank with a sufficient quantity of

gasoline for the initial start-up proceedure.

4. Double check that all fuel line connections

have been made correctly and there is no gas

leakage at any point in the system.

I. Oil Tank, Fittings, and Oil Lines

1. Oil

Tank

Preparation

1. Remove and flush oil tank thoroughly before

installing oil lines. Flush oil cooler also, if so

equipped.

2. Re install oil tank per appropriate OEM manual

3.

Install S&S Oil Tank Fittings

a.

Remove the OEM fittings from the existing

oil tank. (transmission mounted oil tanks

only)

b.

Install S&S supplied fittings using LOCTITE

PIPE SEALANT 565. Tighten to 120-144

in.-lbs.

CAUTION - If engine is run with foreign material in the

oil tank, engine damage will occur. Engine damage

caused by foreign material in the oil tank

is not

covered under the S&S warranty

NOTES:

●

When installing threaded fittings, be careful not to cross-

thread fittings or damage threads. Damage caused by

incorrect hardware installation will not be covered under

warranty.

●

To prevent galling, apply pipe sealant, or Teflon tape to

threads of all steel fittings prior to installation in crankcase.

●

If Teflon tape is used, loose tape must not enter

crankcase or oil passages. Do not apply tape to first 2-3

threads that screw into hole. If fittings are removed or

replaced be sure no tape shreds remain in holes. Tape

shred could block oil passages causing restriction of oil flow.

CAUTION - Restricted oil flow may result in extensive

engine damage not covered under warranty.

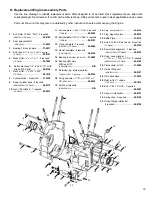

2. Oil conduit block and oil hose installation

See Picture I1

13

Conduit Block

Grade 5 bolt and washer

O-rings

Oil tank fittings

Picture I 1