10

2. Inspect pistons, especially areas around

machined surfaces such as ring grooves and

wristpin holes. De-burr as necessary, taking

care to remove particles that could become

dislodged inside engine.

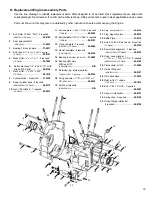

3. Measure ring end gaps and adjust as

necessary. See Pictures E13 and E14

a. Compression ring end-gaps should be

between .017” to .025”.

b. Oil ring rail end-gaps should be between

.015” to .035”.

4. Thoroughly clean cylinders, pistons, rings,

wristpins, and wristpin retainers in solvent,

then hot, soapy water. Take special care to

flush oil passages. Dry all with compressed air,

lightly coat all bare steel surfaces with

assembly lube, and place on clean, dry

surface.

5. S&S recommends installing all cylinder base

gaskets dry. Be sure holes in gaskets align

with cylinder base dowels and oil holes.

NOTE - cover cylinder studs with rubber hose to protect

piston and rings until cylinders are installed.

6.

Install rings on pistons.

NOTE - The high wrist pin location on 124” pistons requires

an additional support for the oil rings at the gap on each

side of the wrist pin. This stiff ring should be installed first.

a.

Install oil ring lower support in bottom

piston ring groove,with the dimple facing

down, and located in piston pin gap.

b. Lubricate wristpin, wristpin bushing, and

wristpin bore in piston with assembly lube.

Raise the previously installed support ring

in the lower groove to allow the wrist pin to

slide in under it. Install wristpin through

piston and connecting rod, secure with

new retaining clips, two per piston.

c. The moly-faced ring is installed in the top

piston ring groove, chamfer-side up.

d. The plain cast ring is installed in the

second piston ring groove, dot up.

e. Install the oil ring expander in the lower

ring groove (on top of the previosly

installed support ring), then install one oil

ring rail on either side of the expander.

f. Stagger all ring end-gaps

NOTE - S&S recommends the use of clip installer, part

number HD 42317, available from Kent-Moore, through

Harley-Davidson, or similar tool, for clip installation.

See Picture E15.

7. Install cylinder head alignment dowels in

cylinder.

8.

Apply very light film of motor oil to piston skirts

and cylinder bores and install rear cylinder.

Install rear cylinder head, referring to following

section as necessary.

NOTE - On Twin Cam style Engine, if engine builder

chooses to install front cylinder before installing rear head,

rear cylinder should be temporarily secured with head bolt

and washers. If cylinder is not secured, piston can lift

cylinder and disturb base gasket if flywheels rotated.

9.

Repeat piston installation for front cylinder and

cylinder head.

Picture E15

Picture E14