50

Scan Board setting

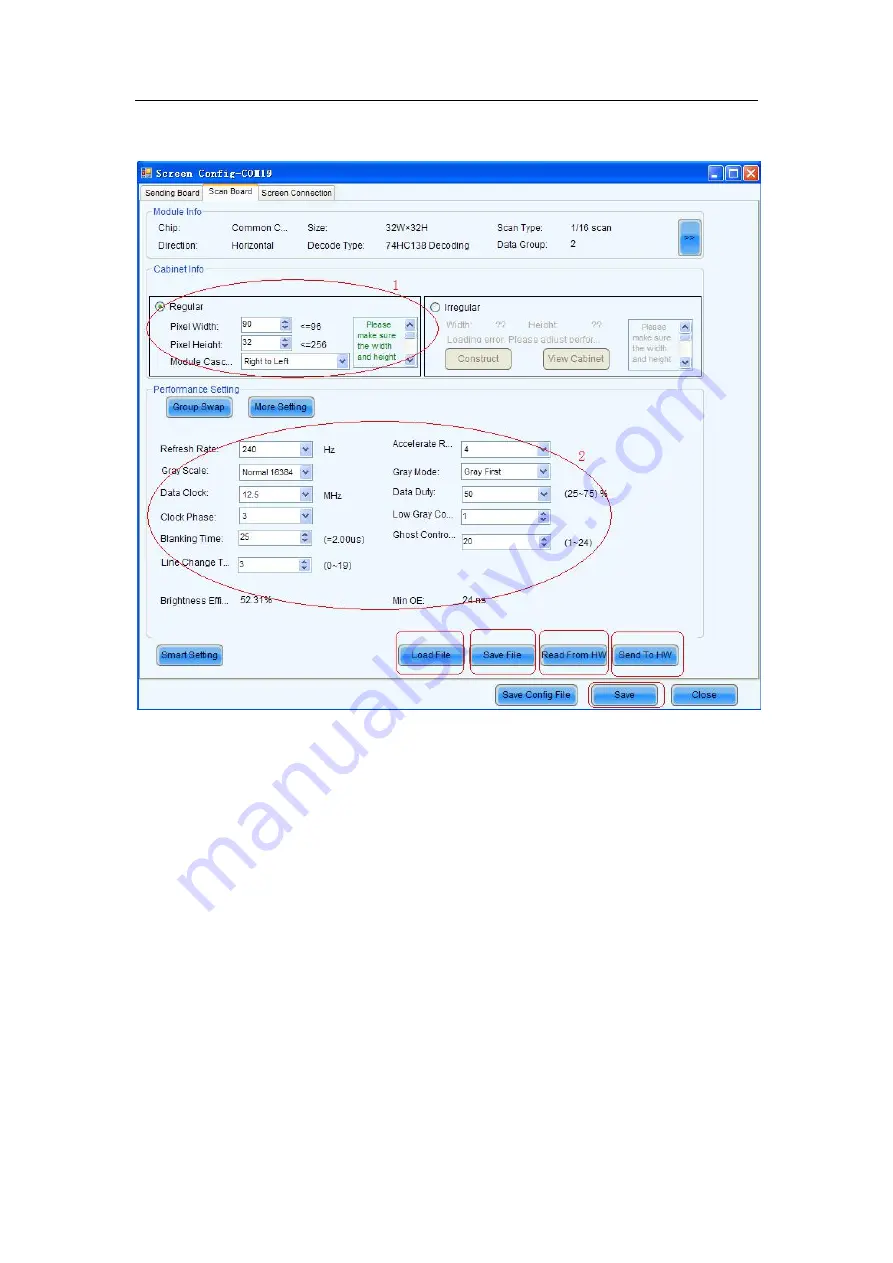

Choose the `Scan Board` as shown in Fig 9-7.

Fig 9-7

LoadFile:

Load programmer file from PC, the file is saved and sent out by the

manufacturer.

Save file:

Save one new programmer file after adjusting parameter.

Read From HW:

Read the programmer parameter which is saved into the scan boards in

cabinets.

Send to HW:

Send the programmer parameter which is loaded to all the scan boards in

cabinets.

Save:

Save the programmer parameter which is sent to all the scan boards in cabinets.

After saving, you will not need to operate again.

Attention:

We have loaded relative program to the receiving cardbefore delivery and the

file is also within the package of goods. It is unnecessaryto follow this step, ONLY if you

must operate it.

Summary of Contents for XA100F

Page 1: ...1 Outdoor P10 Product User Manual Model Name XA100F Model Code LH100XAFSSC ...

Page 11: ...11 3 2 Product Appearance ...

Page 12: ...12 3 3 Product design Decomposition chart ...

Page 13: ...13 Assembly drawing ...

Page 14: ...14 3 4 Product main components Module Power Supply Receiving card Fan ...

Page 15: ...15 DC output cables 9 pcs Flat cables 9 pcs ...

Page 33: ...33 Installation of cabinets Fixing of connect plate ...

Page 39: ...39 8 2 Port of Cabinet and serial number paint ...

Page 56: ...56 ...

Page 65: ...65 ...

Page 98: ...98 ...

Page 114: ...114 Install the cover for connection cable Power on the cabinet ...

Page 115: ...115 Signal input cable and Signal cascade cable Remove the bad one Install the new one ...