Alignment and Adjustment

Samsung Electronics

2-3

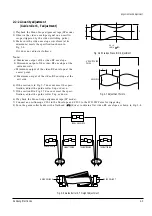

2-2-2 Linearity adjustment

(Guide roller S, T adjustment)

1) Playback the Mono Scope alignment tape (SP mode).

2) Observe the video envelope signal on an oscillo-

scope (triggered by the video switching pulse).

3) Make sure the video envelope waveform (at its

minimum) meets the specification shown in

Fig. 2-6.

If it does not, adjust as follows :

Note :

a=Maximum output of the video RF envelope.

b=Minimum output of the video RF envelope at the

entrance side.

c=Minimum output of the video RF envelope at the

center point.

d=Maximum output of the video RF envelope at the

exit side.

4) If the section A in Fig. 2-7 does not meet the speci-

fication, adjust the guide roller S up or down.

5) If the section B in Fig. 2-7 does not meet the speci-

fication, adjust the guide roller T up or down.

Fig. 2-6 Envelope Waveform Adjustment

a

a b c d

c,b,d/a 63%

b

c

d

Fig. 2-7 Adjustment Points

A

B

A

B

H'D SWITCHING

PULSE

ENVELOPE

6) Play back the Mono Scope alignment tape (SP mode).

7) Connect an oscilloscope CH-1 to the Envelope and CH-2 to the H’D SW Pulse for triggering.

8) Turn the guide roller heads with a flat head ( ) driver to obtain a flat video RF envelope as shown in Fig. 2-8.

Fig. 2-8 Guide Roller S, T Height Adjustment

IDEAL ENVELOPE

S HEIGHT TOO HIGH

S HEIGHT TOO LOW

T HEIGHT TOO HIGH

T HEIGHT TOO LOW

GUIDE ROLLER S

GUIDE ROLLER T

Summary of Contents for SV-G180UM

Page 10: ...2 6 Alignment and Adjustment Samsung Electronics MEMO ...

Page 18: ...Exploded View and Parts List 3 8 Samsung Electronics MEMO ...

Page 32: ...Schematic Diagrams 5 4 Samsung Electronics 5 2 S M P S Power Free Voltage ...

Page 33: ...Schematic Diagrams Samsung Electronics 5 5 5 3 Logic Ø ˆ Œ ˇ Ω ...

Page 35: ...Schematic Diagrams Samsung Electronics 5 7 5 4 Audio Video ˇ ˆ Ø Œ ...

Page 37: ...Schematic Diagrams Samsung Electronics 5 9 5 5 Hi Fi Option Œ ˇ ...

Page 42: ...Schematic Diagrams 5 14 Samsung Electronics MEMO ...

Page 61: ...1 18 Samsung Electronics Disassembly and Reassembly MEMO ...