32

Purging the unit

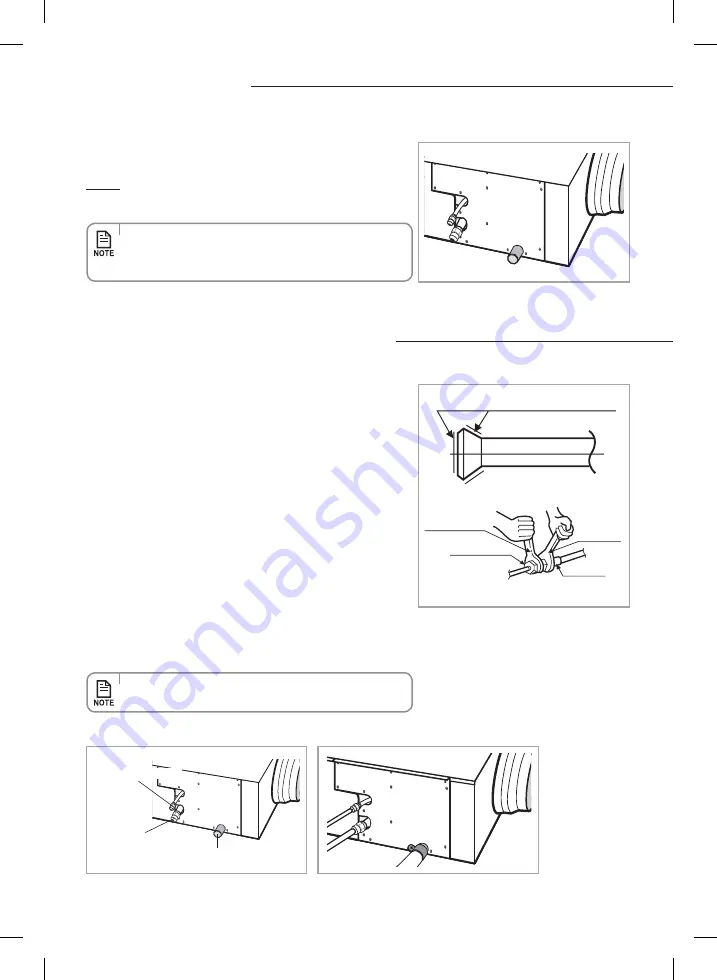

Unscrew the pinch pipe at the end of each refrigerant pipe.

Result:

All inert gas escapes from the indoor unit.

On delivery, the indoor unit is loaded with inert gas. All this gas must therefore be purged before connecting the

assembly piping. To purge the inert gas, proceed as follows.

•

T

o prevent dirt or foreign objects from getting into the pipes

during installation, do NOT remove the pinch pipe completely

until you are ready to connect the piping.

The designs and shape are subject to change

according to the model.

Connecting the refrigerant pipe

1. Remove the pinch pipe on the pipes and connect the assembly pipes

to each pipe, tightening the nuts, first manually and then with a

torque wrench, a spanner applying the following torque.

Outer Diameter

Torque (kgf•cm)

6.35 mm (1/4")

145~175

9.52 mm (3/8")

333~407

12.70 mm (1/2")

505~615

15.88 mm (5/8")

630~769

2.

Ensure there are no kinks or cracks on pipe bends.

There are two refrigerant pipes of differing diameters:

A smaller one for the liquid refrigerant

A larger one for the gas refrigerant

The inside of the copper pipe must be clean, dry and free from debris.

The connection procedure for the refrigerant pipes varies according to

the exit position of the pipes from the indoor unit, as seen when facing

the indoor in the “A” side.

Liquid refrigerant port

Gas refrigerant port

Drain hose port

The designs and shape are subject to change according to the model.

Refrigerant oil

Torque wrench

Flare nut

Union

Spanner

• Must apply refrigerant oil on the flaring area to prevent a leak.

Drain hose connection port

Gas refrigerant port

Liquid refrigerant port

A

RHF050KHEA_IB,IM_E_32885-3.indd 32

2011-10-12 오후 5:30:32