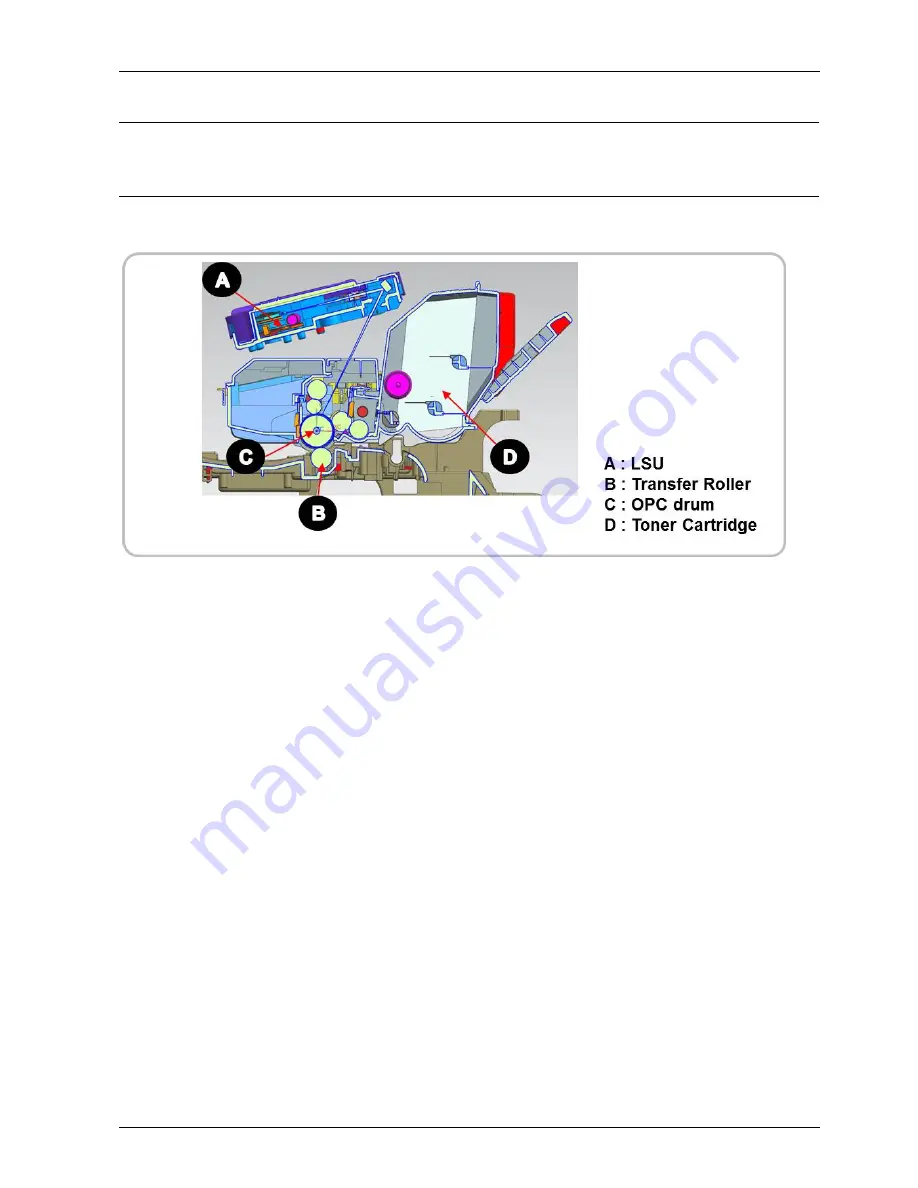

2. Product Specifications and Description

2.5. Image Creation

2.5.1. Printing process overview

This machine uses a toner cartridge, transfer roller, and LSU for mono printing.

The toner cartridge as integrated type consists of the toner bottle, drum unit and development unit. The drum unit

consists of an OPC drum, charge roller, cleaning roller, and cleaning blade. The development unit consists of the deve.

roller, supply roller, Dr.blade, and agitator.

The OPC drum is charged with a negative voltage by the charge roller and is exposed by the light from the LSU (Laser

Scanning unit).

The light produced by a laser creates a latent image by discharging on the surface of the OPC drum. The negatively charged

toners are attracted to the latent image due to the electric field. The toner(real image) on the OPC drum are moved to the

paper by the positive bias applied to the transfer roller.

1)

OPC drum charge

: The charge roller gives the OPC drum a negative charge.

2)

Laser exposure

: Light produced by a laser diode(LD) hits the charged OPC drum through the lens and mirrors. The

machine controls the laser beam on/off for the latent image.

3)

Development

: The developing roller carries the negatively charged toner to the latent image on the OPC drum surface.

4)

Transfer :

The negatively charged toner is transferred to the paper by transfer voltage.

5)

Cleaning for OPC drum

: The cleaning blade remove remaining toner on the OPC drum surface after image transfer

to the paper.

Copyright© 1995-2013 SAMSUNG. All rights reserved.

2-22