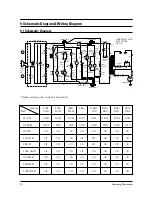

8. P.C.B Diagrams

8-1 P.C.B Diagrams

Samsung Electronics

8-1

MICOM

V.F.DISPLAY

SVM-4MS-13

100K

-20V

F1

F2

R29 3.9K-J

100K

100K

KA2657

12V

12V

5V

12V(A)

D08

1N4001

MAIN

RELAY

F1

F2

R01 470-J

R02 470-J

ZD01 1W 5.1V

-20V

D01 1N4001

C02

470uF

D02 1N4001

-20V

C05

0.1uF

C06

0.1uF

D04 1N4001

5V

G3 37

G2 36

G1 35

G0 34

B0 45

B1 46

B2 47

B3 48

B4 49

B5 50

B6 51

B7 52

H7 32

H6 31

H5 30

H4 29

H3 28

H2 27

H1 26

H0 25

A4 8

A5 9

A6 10

A7 11

15 INT

64 VCC

3 VREF

12 RESET

2 VASS

1

V

SS

63 OSC IN

62 OSC OUT

41 G7

14 E1

23 C6

24 C7

16 E3

13 E0

5 A1

4 A0

6 A2

7 A3

17 C0

18 C1

19 C2

20 C3

21 C4

22 C5

IC 1

C18 0.1uF

+

C01

470uF

IC2

1

2

3

4

5

6

8

16

15

14

13

12

11

9

+

+

C07

0.1uF

+

R08 10K-J

Q04

R1005

R03 470-J

ZD02

0.5W 13V

D03

1N4148

C03

1000uF

Q01

D882Y

12V

VTG-REG

7805

C04

100uF

5V

ZD03

0.5W3.9V

R04

1K-J

R05

1K-J

R06

5.1K-J

Q02

C815

Q03

C815

R07

10K-J

+

C11

10uF

12V

12V(A)

Q09

A539

12V

12V

BUZZER

Q07 R2005

R12 10K-J

R11 3.9K-J

Q08

R1005

D05

1N4001

+

D06 1N4001

R10

2K-J

Q06

R1005

R09 1K-J

Q05

R1005

C09 27pF

C08 27pF

D07

1N4001

Q10

C815

POWER

RELAY

R13 3.9K-J

R14

10K-J

12V(A)

R16

10K-J

R15

3.9K-J

Q11

C815

5V

+

C15

1uF

5V

ENCODER

SWITCH

R25 1K-J

R26 1K-J

R27 10K-J

R28 10K-J

DOOR S/W

CON03

THERMISTOR

C12

0.1uF

R23 2K-J

R38 1M-J

R37 1M-J

R24 1K-F

R22 5K-F

Q12 A539

R21 10K-J

R18 3.9K-J

R17 3.9K-J

R19 100K-F

R20 3.9K-J

INRUSH RELAY

GRILL RELAY

FAN RELAY

DAMPER RELAY

CONV.M RELAY

CONV.H RELAY

33

53

54

55

56

57

58

59

60

TIME

COOK

COMBI 2

(M+C)

MIN+

MIN-

START

OPTION

OPTION

-20V

G1

G2

G3

G4

p

o

n

m

l

k

j

i

h

g

f

e

d

c

b

a

R30 3.9K-J

R31 3.9K-J

R32 3.9K-J

8

7

10

9

GRILL

CONVEC-

TION

COMBI1

(M+G)

AUTO

COOK

AUTO

DEFROST

COMBI 3

(G+C)

POWER

LEVEL

CLOCK

CANCEL

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

1N4148

D10

1N4148

D11

1N4148

D12

1N4148

D13

1N4148

D14

1N4148

D15

1

2

3

4

5

6

R33

47K-J

R34

47K-J

R35

47K-J

R36

47K-J

P.C.B.-SUB

C14

332

C15

332

C16

332

C17

332

MICOM OPTION

CON01

1

2

3

6

4

5

1 tone

2 tones

4 tones

5

6

3

2

1

(B)

(A)

(A)

Waveform of (A)

0V

-5V

DC

Waveform

of

(B)

0V

-5V DC

0V

Waveform of (A)

VCC (-5V

)

Waveform

of (B)

VCC (-5V

)

ZD4

Turn off

Power Off

Power On

1. Beep tone

2. Stage change and

half time in Auto Weight

Defrost tone

3. Error and Finish Tone

0.1sec

0.6sec

0.4sec

0.6sec

0.4sec

0V

-5V

Pin

5

0V

V

1

V1

Pin 4

-3V

T

CH1gnd

CH2 gnd

CH1 5V A 200ms 2.21 V VERT

CH2 5V 5V

CH1

CH2

CH2 MAX - 5.16V

CH1 5V A 200ms 2.21 V VERT

CH2 2V -354.00ms

CH1gnd

CH2 gnd

CH2 MAX - 5.16V

0

-2

-4

-5V

-6

6

5V

4

2

0

4

(B)

C10 10uF