EB 8048 EN

41

Servicing

Risk of contamination of the process me-

dium through the use of unsuitable lubri-

cants and/or contaminated tools and com-

ponents.

Î

Keep the valve and the tools used free

from solvents and grease.

Î

Make sure that only suitable lubricants

are used (

u

The control valve was checked by SAMSON

before it left the factory.

− Certain test results certified by SAMSON

lose their validity when the valve is

opened. Such testing includes seat leakage

and leak tests.

− The product warranty becomes void if

service or repair work not described in

these instructions is performed without

prior agreement by SAMSON's after-sales

service.

−

Only use original spare parts by

SAMSON, which comply with the original

specifications.

9.1 Periodic testing

Depending on the operating conditions,

check the valve at certain intervals to prevent

a possible failure before it can occur. Opera-

tors are responsible for drawing up an in-

spection and test plan.

Our after-sales service can support you in

drawing up an inspection and test plan for

your plant.

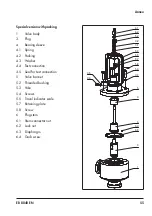

9.2 Preparing the valve for

service work

Standard version

1.

Put the control valve out of operation (see

section 10).

2.

Remove the actuator from the valve. See

associated actuator documentation.

3.

Unthread the lock nut (6.2) and stem

connector nut (6.1) from the plug stem

(6).

4.

Undo the clamp connection between the

valve body (1) and valve bonnet (5).

5.

Lift the valve bonnet (5) together with the

plug stem (6), plug (3) and diaphragm

(6.3) off the body (1).

6.

Pull the plug (3) with plug stem (6) and

diaphragm (6.3) out of the valve bonnet

(5).

Special version

1.

Put the control valve out of operation (see

section 10).

2.

Remove the actuator from the valve. See

associated actuator documentation.

3.

Unthread the lock nut (6.2) and stem

connector nut (6.1) from the plug stem

(6).

4. Undo the hex screws (5.4).

NOTICE

!

Note

Tip