www.larius.com

7

REV.

1 - 06/2020 - Cod. 150142

3

Fig. 2E

2

9

7

1

8

4

3

5

6

10

10

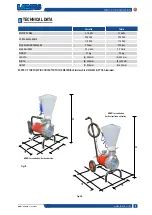

Miro' for sanitation

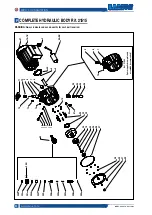

MIRO' FOR SANITATION VERTICAL SUCTION

Pos.

Description

1

Electric / combustion motor

2

High pressure manometer

3

Setting valve

4

Hydraulic oil filling cap

5

Hydraulic body

Pos.

Description

6

Colour body

7

Tank

8

Circulation tap

9

Recirculation tube

10

Feed tube connection