Revised A

24

6301

3.3. Operating principle

3.3.1. Turbine rotation speed

The reading is obtained using a microphone. The air supply arrives at the clip holding the bellcup.

This clip is machined with a groove in which air passes with every rotation of the bellcup. This pres-

sure variation causes a noise or “frequency signal”, which is sent through the injector holder to a

microphone. The microphone in turn converts this frequency signal into electrical variations which are

sent to the speed regulation board.

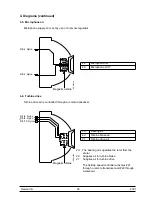

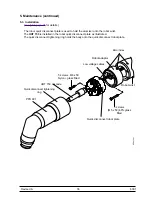

3.3.2. Microphone

1

Half moon groove

2

Microphone air return (Mic. OUT)

3

Microphone air supply (Mic. IN)

4

Microphone

5

Speed regulator board

6

Manual air regulator

7

1/4” Tube = (15 to 26 ft) or (4.5 to 8m)

8

Microphone air return1/4” tube

9

Microphone assembly (w/connector)

P/N: 851488 (6mm)

P/N: 459881(1/4”)

10

Microphone sleeve

PN: 546994

11

Microphone cable assembly

PN: 63-1080-00 (40m w/connector)

DES01241

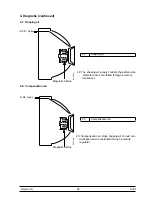

For extra hose length,

increase microphone IN pressure 0.6 psi/feet of tubing

OD

1/4” tube

26 feet / 8m

Maximum length

15 feet / 4.5m

Required minimum length

Microphone IN

Required pressure

25 - 45 PSI

DES01295

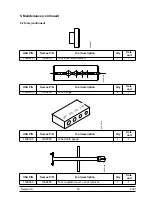

7

11

9

10

8

E

S01486

Mic Return air (Mic OUT)

To speed control board