Revision index: E - May 14

th

, 1998

- 10 -

Code : RT 6015

4. MAINTENANCE

4.1. PERIODICAL MAINTENANCE AND CHECK-UPS

IMPORTANT : All cleaning work should be carried out using compressed air, rags or if necessary brushes. Water should

NEVER be used.

Spray gun soiling and wear, caused by powder flow, clearly depends on the type of powder used.

The guidelines as to cleaning and maintenance frequency provided in the table below can only be taken as an indication of

what is required. Users of BINKS-SAMES equipment should develop their own maintenance programmes.

As a first approach we recommend the following programme:

MAINTENANCE FREQUENCY

ACTION

•

Before starting work.

•

Check rules 3, 4 and 6 of section 2.1.

•

Every day.

•

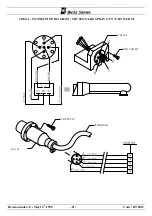

Remove the nozzles from the SRV 028 spray gun and

clean the electrode with a brush.

•

Clean the nozzles with compressed air.

•

Between 150 and 300 hours (or more).

•

Replace the nozzle if grooves are visible inside nozzle.

4.2. DISMANTLING AND RE-ASSEMBLY (GENERAL)

Dismantling and re-assembly of these complex assemblies are described in Chapter 6.

Easy and frequent component dismantling:

∗

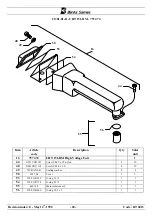

SRV 028 spray gun (refer to plate BF04).