10-19

a.

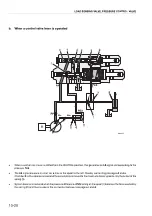

When the directional control valve is in «NEUTRAL»

·

The pressure

PLS

of the

LS

from the control valve outlet enters the chamber

a

of the

LS

valve spring; the pump de-

livery pressure PP enters the chamber

b

on the opposite side of the spool.

·

The position of the spool (1) is determined by the combination of the force created by the pressure

PLS

plus the force

exerted by the spring (2) and by the force exerted in the opposite direction by the pressure

PP

.

·

Before the engine is started, the control piston (6) is pushed by the spring (5) to the right (corresponding to the max-

imum swash plate angle).

·

When the engine is started, all the control valve spools are in «NEUTRAL», the pressure

PLS

of the

LS

signal remains

at 0 bar (0 psi) as no fluid is delivered from the control valve outlets and the signal is connected to drain.

At the same, the pump delivery pressure

PP

increases as there is no demand from the users.

When the force exerted by the pressure

PP

in chamber

b

balances the force exerted by the spring (2), the spool (1)

moves to the right and allows the fluid at pressure

PP

to flow into the chamber

X

of the piston (6) by connecting pas-

sages

c

and

d

.

·

The force exerted by the fluid pressure on the piston (6) overcomes the force of the spring (5). The control piston is

thus pushed to the left, i.e. towards the minimum swash plate angle position.

·

The pump delivery pressure

PP

stabilizes around the value of 18 bar (261 psi), which corresponds to the standby

pressure.

M

Min

Max

D0000460

8

7

6

5

2

1

PLS

T

PEN

PP

X

b

PP

a

c

d

e

LOAD SENSING VALVE, PRESSURE CONTROL VALVE