10-15

OPERATION

1.

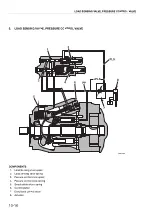

Operation of the pump

1 - The cylinder block (4) rotates with the shaft (1)

and the piston shoes (6) slide over the flat sur-

face «

A

».

The swash plate (3) moves over the cylindrical

surface «

B

»; the angle «

a

» between the axis of

the shaft (1) and the axis

X

of the swash plate (3)

can be changed to alter the stroke of the pistons.

Angle «

a

» is known as the «swash plate angle».

2 - When axis

X

of the swash plate (3) is at an angle

«

a

» to the shaft (1) and consequently also the

cylinder block (4), the surface «

A

» acts as cam

for the piston shoes (6). As a result, as the shaft

rotates, the pistons (5) stroke inside the cylinder

block (4), thereby creating a difference in the vol-

umes

C

and

D

and thus drawing in and discharg-

ing oil in a quantity equal to this difference in

volume (

D

--

C

=delivery).

In other terms, when the cylinder block (4) ro-

tates, the volume of cylinder

D

is reduced, there-

by forcing out the oil, while the volume of cylinder

C

is increased, thereby drawing oil into the bore.

(Fig. 1 shows the pump condition on completion

of the suction phase in cylinder

D

and the deliv-

ery phase in cylinder

C

).

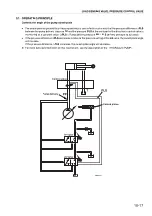

3 - When the axis

X

of the swash plate (3) is parallel

to the axis of the cylinder block (4) (swash plate

angle «

a

»=0), the difference in volume between

C

and

D

inside the cylinder block (6) is 0 and

therefore no oil is pumped (Fig. 2).

(In reality, the swash plate «

a

» is never exactly

equal to zero 0).

4 - Pump delivery is therefore directly proportional

to the swash plate angle «

a

».

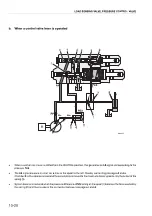

2.

Pump delivery control

·

When the swash plate angle «

a

» is increased,

the difference between volumes

C

and

D

in-

creases and consequently so does the pump

delivery

Q

.

The swash plate angle is changed by the control

piston (8).

·

The control piston (8) moves in accordance with

the pressure signals received from the Load

Sensing valve and the pressure control valve.

The linear movement of the piston is transmitted

to the swash plate (3), which is supported by the

cylindrical surface of the pump housing (2); the

swash plate thus moves through a semicircular

arc (Fig. 3).

D0000530

4

C

6

S

A

3

1

x

␣

B

D

D

4

C

3

x

Fig. 1

Fig. 2

D0003210

C

8

␣

D

3

2

Fig. 3

HYDRAULIC PUMP