Operator's Manual

Round bale wrapper

Spin S, Spin F

- 27 -

The bales should be wrapped only in positive temperatures. The bales should be wrapped on a

field or in their storage area.

Pay particular attention the initial tensioning of the film (65-80%)

1

. A worn or unlubricated

tensioning mechanism may cause the film the be wrapped too tughtly. The film tensioning level

must not exceed 70%.

Pull the film at the first bale as far as possible from the feeder and attach it using the string

binding the bale. Using the control lever, turn on the hydraulic motor of the wrapping machine.

While placed on the rotary table, the bale is rotated by a certain angle around its horizontal axis

with every revolution around its vertical axis, which causes the overlapping of consecutive layers of

film resulting in a tight wrap around the bale. Maintain the tractor engine’s revolutions at 1500

RPM while wrapping.

Wrap at least 4 layers of film so that each of tchem is overlapped in 50%.

We advise to finish the wrapping after about 24 revolutions of the rotary frame while using

1' 8"

film or 16 revolutions while using

2' 5"

film. Secure the end of the film. A properly wrapped bale

has four layers of the wrapping film around it.

1

Mark two vertical lines on the film in a distance of about 4

"

from each other. The distance

between the lines of 7

"

after tensioning represents 70% of the initial film tension. The width of the

film measured at the end of the bale may not be lower than 1

' 4"

when using

1' 8"

film and not lwer

than

1' 12"

when using

2' 5"

film.

CAUTION!

Before turning on the rotary frame drive, make sure that there are no

bystanders in the working area.

CAUTION!

Maintaining the Rolls in good condition, especially their edges, minimises

the risk of the film breaking while wrapping.

WARNING!

Do not wrap during precipitation.

If the bale is wrapped too tightly, halt the wrapping process. Establish the cause of excessive

film tension. Set the proper film tension. Resume the wrapping process.

Use the bales within 12 months from their wrapping date.

8.5.

Unloading the wrapped bale

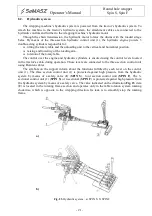

To unload the bale, stop the rotary table about 25° beyond the axis parallel to the wrapping

machine’s axis and move the table back using the control switch lever to a position parallel to the

machine’s axis until the rotary table is locked.

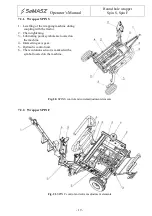

In SPIN S bale wrapper the conical Rolls located on the sides of the rotary frame prevent the

film from falling off the drums while wrapping.

The film cutting system should be located in front of the wrapping machine. The unloading of

the bale is completed by lifting the rotary table with the bale as ahown on the Fig. 29. Wrapped bale

slides down freely to the ground.