3

XL-TG20004BM-en-US · 2014-01-14 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

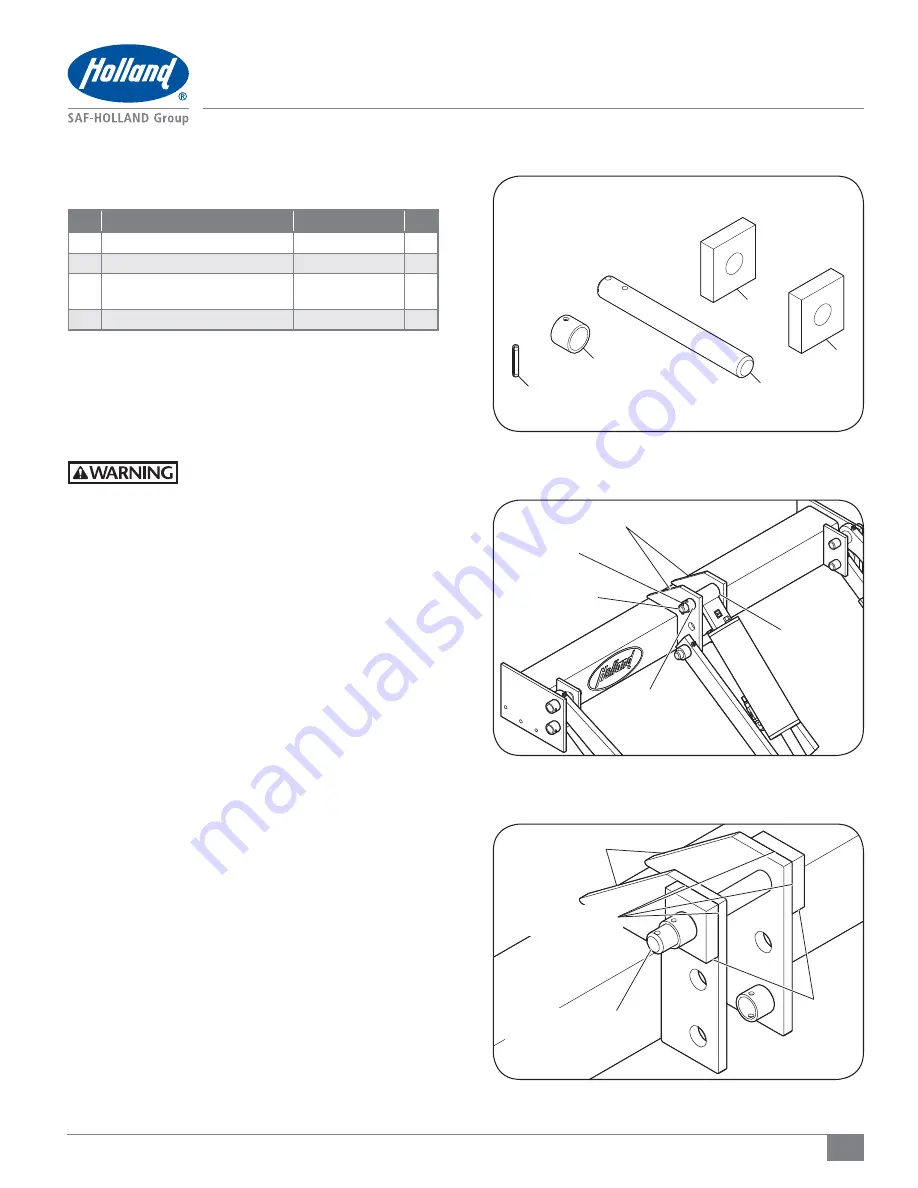

Figure 2

Kit Contents and Bushing Installation

3.

Kits Contents

(Figure 2)

ITEM DESCRIPTION

PART NUMBER

QTY.

1

Lift Frame Boss

2112100004580

2

2

Sleeve, 1-5/16" O.D. x 1" Long

XA-50194

1

3

Hydraulic Cylinder Mounting Pin,

1" Diameter x 8-1/2" Long

XA-50020

1

4

Pin, Spring 1/4" x 1-1/2", Plated

XB-21-S-250-1500P

1

4. Bushing Installation

1. Open and lower the liftgate to the ground in accordance

with the TL and TG Series Operation and Maintenance

Manual XL-TG10150UD-en-US. Avoid contact with electrical

connections inside the pump box which are not isolated.

Failure to avoid contact with electrical

connections will result in shock which,

if not avoided, could result in death or

serious injury.

2. Disconnect the power to the motor.

3. With a punch, remove the spring pin from the hydraulic

cylinder mounting pin

(Figure 3)

.

4. Remove the pin and rotate the hydraulic cylinder clevis

out of the mounts

(Figure 3)

.

5. With a grinder, remove the sleeve from the cylinder

mount

(Figure 3)

.

6. Align the new parts. Insert the new pin through one lift

frame boss, both cylinder mount plates and then through

the second lift frame boss

(Figure 4)

.

7. Prep the cylinder mount surfaces where the lift frame

bosses will be welded. With a grinder, remove any paint

or galvanizing within 1" to 4" (25-101 mm) of the weld

surface. Position the lift frame bosses and align the top

and leading edge of the lift frame bosses flush with the

top and leading edge of the cylinder mounts

(Figure 4)

.

Bushing Kit

Part Number: 2074300000090

1

1

2

4

3

Figure 4

Figure 3

CYLINDER MOUNTS

CYLINDER MOUNTS

TOP AND LEADING

EDGE FLUSH

HYDRAULIC

CYLINDER

CLEVIS

LIFT

FRAME

BOSS

SPRING PIN

HYDRAULIC CYLINDER

MOUNTING PIN

HYDRAULIC CYLINDER

MOUNTING PIN

SLEEVE