EN - 14

ASSEMBLY

1. Unpack all parts and lay them on a flat, stable surface:

2. Remove all packing materials and shipping devices, if

applicable.

3. The scope of delivery varies depending on the country

and purchased variant:

Model of BLB4QL-M-EU

• Power tool x1

• Instruction manual x1

• Control pipe x1

• Intermediate pipe x1

• Blower pipe x1

• Clamp x2

• Wire clamp x1

• 200ml bottle of engine oil x1

4. If you find that parts are missing or show damage do

not use the product but contact your dealer. Using an

incomplete or damaged product represents a hazard to

people and property.

5. Ensure that you have all the accessories and tools

needed for assembly and operation. This also includes

suitable personal protective equipment.

WARNING:

Wear protective gloves for this assembly work

and always lay the product on a flat and stable

surface while assembling.

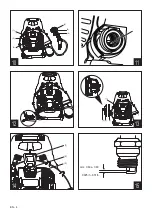

Follow the assembly instructions step-by-step

and use the pictures provided as a visual guide

to easily assemble the product!

Never install, remove, or adjust any attachments

while power head is running. Failure to stop the

engine can cause serious personal injury.

CONNECTING THE BLOWER PIPE

ASSEMBLY

1. Mount the control pipe to the flexible pipe. reinforce the

connection by the clamp(Fig.2).

2. Attach the handle to the control pipe. Lock the nut to fix

the handle when adjusted to the best operation position.

Double secure the handle by the quick clip (Fig.3).

3. Install the flexible pipe on the elbow of the blower and

tighten the clamp. Use the wire clamp to secure the

throttle line(Fig.4).

4. Align and rotate 90° for attaching the Intermediate pipe

to the control pipe. Make sure the Intermediate pipe is in

place and tighten the screw (Fig.5).

5. Align and rotate the blower pipe 90° clockwise for

mounting it on the Intermediate pipe. Tighten the screw

for keep the pipe firmly in place(Fig.6).

NOTE:

There are professional guide rails on intermediate pipe and

blower pipe. Properly alignment will contribute to the totally

insertion. Slightly lubricate the guide rails with detergent if it

is difficult to fit. The disassembly steps are just the opposite,

loosen the screw, rotate counterclockwise and pull the pipe

out.

FUEL AND OIL

USING THE RIGHT OIL

Use a high-quality SAE 30 weight oil. DO NOT use dirty

oil. Failure to use clean oil of the correct type can cause

premature engine wear and failure.

ADDING OIL: INITIAL USE

WARNING:

OVERFILLING THE CRANKCASE MAY CAUSE

SERIOUS PERSONAL INJURY. Check the

oil level before each use. The importance

of maintaining the proper oil level cannot be

overemphasized. Change the oil according to

the Maintenance Schedule.

NOTE:

This unit was shipped without oil in the crankcase. Oil must

be added before starting the unit. This unit comes with a

bottle of oil.

1. Set the unit on a flat, level surface.

2. Unscrew the oil tank cap (Fig.7).

3. Pour the supplied oil into the oil tank. Only add

170ml(5.7 fluid oz.) oil. Do not overfill. Refer to

CHECKING THE OIL LEVEL.

NOTE:

Never add oil to the fuel tank. This unit has a four-cycle

engine. DO NOT mix oil with gasoline.

4. Wipe up any oil that may have spilled.

5. Reinstall the oil tank cap. Make sure the O-ring is in

place on the oil fill plug.

WWW.SABREITALIA.COM

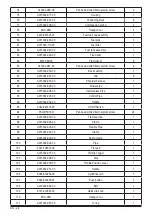

Summary of Contents for 4SISON BLB4QL-M

Page 2: ...1 2 3 4 5 6 7 8 9 10 11 12 15 17 16 14 13 1 2 3 IT 2 WWW SABREITALIA COM...

Page 3: ...4 6 9 7 5 8 IT 3 ABREITALIA COM WWW S...

Page 21: ...IT 21 ESPLOSO RICAMBI WWW SABREITALIA COM...

Page 26: ...1 2 3 4 5 6 7 8 9 10 11 12 15 17 16 14 13 1 2 3 EN 2 WWW SABREITALIA COM...

Page 27: ...4 6 9 7 5 3 EN 8 WWW SABREITALIA COM...