PLASTIC MOULDINGS

V

IA DELL

’

ARTIGIANATO

,

6

•

61026

LUNANO

(PU)

•

I

TALY

T

EL

.

+39

0722

722801

•

F

AX

+39

0722

70599

•

W

EB

:

www.rototec.it

E-

:

•

PEC

VAT

and TAX

CODE

01476690415

•

C

OMPANY

C

APITAL

.

120.000,00

CCIAA

(C

HAMBER OF

C

OMMERCE

R

EG

.

N.)

12602

P

ESARO

DEPURO ONE Use and Maintenance Manual, Rev. 00 of 27/01/2016

Page 11 of 13

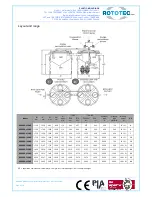

9. UNDERGROUND INSTALLATION

N.B. The best location for the tank is specified by the designer according

to his own technical evaluation. These installation instructions provide the

guidelines to follow during installation.

Warnings:

A) When carrying out any of the operations, comply with

Legislative

Decree

81/2008

and

subsequent

amendments governing safety at permanent or

temporary construction sites.

B) On arrival of the goods, carefully check the material

to make sure it corresponds to the order and the project

data. Any defects and/or damage due to transport must

be reported immediately. Contact the company directly

by telephone, fax or e-mail.

C) Check that the product is provided with all the standard

documentation (technical data sheets, underground

installation instructions, etc.…). Inform the company of

any missing documents. A copy will be sent

immediately.

D) Make sure that the gaskets, pipes and all the various

parts other than in polyethylene are suitable for the

liquid to be contained.

E) Avoid impacts and contact with sharp-edged objects

that could compromise the integrity of the product.

F) Only handle the tanks when they are completely

empty and then using the lifting eyes (where provided).

NEVER lift the tanks by the inlet or outlet pipes.

G) For the choice of backfill material and compaction

methods, refer to European Standards UNI-ENV 1046

and UNI EN 1610.

H) During the installation works, mark the boundary of the

working area with suitable warning signs.

WARNINGS AND PRECAUTIONS

The installation methods are valid for all

underground tanks:

Corrugated treatment tanks

Corrugated treatment tanks model Elipse

Reinforced treatment tanks

Modular tanks models Infinitank and Minitank

Smooth treatment tanks

Smooth tanks model Panettone

Smooth tanks model Cisterna

Corrugated tanks model Panettone

Corrugated tanks model Canotto

Corrugated tanks model Cisterna

Treatment tanks with separation baffles

Warnings

A) It is absolutely forbidden to install underground tanks

above ground.

B) It is absolutely prohibited to use the tanks for storing

industrial waste or liquids containing chemical

substances or mixtures that are not compatible with

polyethylene (see compatibility table supplied by

Rototec).

C) Underground tanks are NOT suitable and must NOT

be used for storing diesel fuel.

Handling:

A) Use transport and lifting equipment

adequate for the

load and compliant with current safety regulations when

handling the material.

B) During transport, avoid harsh movements that could

compromise the integrity of the tank.

C) Only lift the tank if it is completely empty. NEVER

stand under a raised load.

D) When lifting, use cables or straps suitable for the load

to be supported and in perfect condition. Hook the

cables or straps onto the lifting eyes present on the

tanks. To prevent the load from becoming unbalanced,

place the lifting cables symmetrically, respecting the

lifting angle which must NEVER be less than 45° (see

figure below).

Horizontal

plane

4

5

°

Lifting angle formed

by cables or straps