PLASTIC MOULDINGS

V

IA DELL

’

ARTIGIANATO

,

6

•

61026

LUNANO

(PU)

•

I

TALY

T

EL

.

+39

0722

722801

•

F

AX

+39

0722

70599

•

W

EB

:

www.rototec.it

E-

:

•

PEC

VAT

and TAX

CODE

01476690415

•

C

OMPANY

C

APITAL

.

120.000,00

CCIAA

(C

HAMBER OF

C

OMMERCE

R

EG

.

N.)

12602

P

ESARO

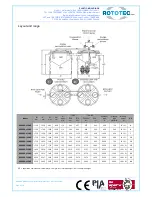

DEPURO ONE Use and Maintenance Manual, Rev. 00 of 27/01/2016

Page 2 of 13

1. INTRODUCTION

The DEPURO ONE treatment plant constitutes a totally biological system for treating domestic sewage and assimilable

effluent (dwellings, hotels, restaurants, etc.) and has been designed, tested and certified in accordance with European

standard UNI EN 12566:3 (Small wastewater treatment systems for up to 50 PT – Part 3: Packaged and/or site

assembled domestic wastewater treatment plants). The tests were carried out at the German PIA Gmbh laboratory

(NB 1739) which issued the certificate for the system as provided for by the European standard.

DEPURO ONE consists of two tanks: a primary tank for sludge separation, digestion and accumulation and an oxidation

tank with recirculation for oxidising the pollutants present in the effluent. Both tanks are manufactured in plastic material

(LLDPE) using rotational moulding technology.

DEPURO ONE can guarantee high levels of domestic sewage purification as regards the principal reference parameters:

BOD

5

, COD, SS (Suspended Solids) and N

tot

(Total Nitrogen).

Advantages of DEPURO ONE:

-

Operating guarantee: the tests carried out according to the European standard under the control of a qualified

laboratory certify the actual sewage treatment levels of the system.

-

High sewage treatment efficiency:

-

Wide range of models for dwellings of 2 to 40 Population Equivalents.

-

Simpler maintenance and reduced management costs.

-

Easy and cheap to install: thanks to the lightweight components.

-

Strength: strong and durable one-piece elements.

-

Respect for the environment: polyethylene is 100% recyclable

.

2. STANDARD UNI EN 12566-3

European standard UNI EN 12566:3 (Small wastewater treatment systems for up to 50 PT – Part 3: Packaged and/or site

assembled domestic wastewater treatment plants) specifies the requirements, test methods, marking and conformity

assessment of packaged and/or site assembled domestic wastewater treatment plants for a population of up to 50

inhabitants. The standard applies to plants constructed using elements in concrete, steel, PVC, Polyethylene (PE),

polypropylene (PP), fibreglass reinforced polyester, polydicyclopentadiene and flexible membranes.

The standard specifies a series of tests that must be carried out by European laboratories qualified at European level.

After having completed all the tests, the laboratory issues a certificate.

The principal tests to which the plant is subjected are:

-

Treatment efficiency test: the plant is tested under normal operating conditions for a period of 38 weeks and the

actual treatment efficiency is determined.

-

Watertightness test: the watertightness is tested on all tanks in the range.

-

Structural behaviour test: simulation of an underground installation with a strength test carried out on the plant.

As required by the European standard, the results of the tests carried out by the PIA Gmbh laboratory (NB 1739) on the

DEPURO ONE are reported on the certificate and are available on request

.