Keeping the World Flowing

17

12.0 Operation

12.6 Hydraulic Manual Override

Single-Acting Actuator

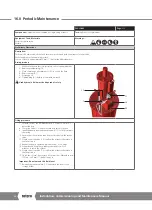

Type HPA hydraulic manual override

The unit consists of two main components:

• the hydraulic cylinder

• the pump/tank assembly

The hand pump (1) supplies high-pressure fluid to the

hydraulic cylinder (2) that will stroke the actuator and

compress the spring.

1

5

4

3

2

Fig 12.11 Type HPA manual override

Installation

The oil tank must be installed in a vertical position with

respect to the floor. The fill port/breather (4) must be turned

upward to avoid any oil discharge from the fill port/breather

of the tank.

NOTE:

Before starting-up the actuator with a hydraulic

override, check if the plug (4) has been replaced with a

breather to prevent oil discharge from the tank during

shipment.

If not, replace the plug with the breather.

Proper oil level is approximately 25 mm (1") below the fill/

breather port.

Oil level should be checked with the tank in a vertical position

and with the actuator in fail position (spring decompressed).

Filling procedure

If the actuator is shipped without oil in the HPA, please refer

to filling procedure described in PM-LP-005.

Operation with Hydraulic Pump

• The manual valve (4) must be in the open position

• Close the on/off selector valve (5) by turning in fully

clockwise

• Operate the pump (1) via the handle (3) will stroke the

actuator and compress the spring

• When the actuator has reached the desired position of

travel, it can be locked in position by closing the manual

valve (4)

• To allow the spring to decompress, the manual valve

(4) must be moved to the open position and the on/off

selector valve (5) backed out by turning anti-clockwise

After each use, verify that the manual override has

been disengaged.

A4

US

US

A4

US

A4

A4

US

Summary of Contents for LP/S Series

Page 89: ...Keeping the World Flowing 89...