Reference

Modification-No.

- 0 -

Page

42

Date

1996 05 10

Install

914 F

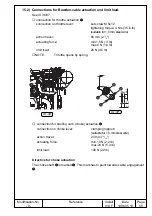

Ill. 23

Q

Q

W

W

13.3) Requirements on the oil- and venting lines

Oil lines

Oil circuit, engine (main oil pump)

➪

Temperature durability:

mind. 130

°

C

(266

°

F)

➪

Pressure durability:

mind. 10 bar

(145 p.s.i.)

➪

Bending radius:

mind. 70 mm

(2,75 in.)

➪

Minimum inside dia. of oil lines in reference to total length

length up to ... 1m (3 ')

min. 11 mm ø (.43")

length up to ... 2 m (6' 6") min. 12 mm ø (.47")

length up to ... 3 m (10')

min. 13 mm ø (.51")

Oil circuit, turbo charger (suction pump)

➪

Temperature durability:

mind. 130

°

C

(266

°

F)

➪

Pressure durability:

mind. 10 bar

(145 p.s.i.)

➪

Bending radius:

mind. 70 mm

(2,75 in.)

➪

Minimum inside dia. of oil lines in reference to total length

length up to ... 1m (3 ')

min. 11 mm ø (.43")

length up to ... 2 m (6' 6") min. 12 mm ø (.47")

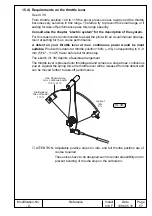

Venting line of oil tank

See ill. 22.

➪

Route the line without kinks and avoid sharp bends.

◆

NOTE:

Water is a by-product of combustion. Most of this water will dissipate

from the combustion chamber with the exhaust gases.

A small amount will reach the crankcase and has to be disposed

through the venting line of oil tank via oil return line.

➪

The venting line must be routed in a continuous decline or furnished with a drain

bore at it's lowest point to drain possible condensate.

➪

The venting line has to be protected from any kind of ice

formation in the condensate. Protection by insulation, or routing

in a hose with hot air flow or by furnishing venting line with a

bypass opening

Q

before passing through cowling

W

. See ill.

23.

Summary of Contents for 914 F

Page 5: ...Reference Modification No 0 Page 5 Date 1996 05 10 Install 914 F Blank page ...

Page 13: ...Reference Modification No 0 Page 13 Date 1996 05 10 Install 914 F Blank page ...

Page 29: ...Reference Modification No 0 Page 29 Date 1996 05 10 Install 914 F Blank page ...

Page 37: ...Reference Modification No 0 Page 37 Date 1996 05 10 Install 914 F Blank page ...

Page 39: ...Reference Modification No 0 Page 39 Date 1996 05 10 Install 914 F Blank page ...

Page 45: ...Reference Modification No 0 Page 45 Date 1996 05 10 Install 914 F Blank page ...

Page 53: ...Reference Modification No 0 Page 53 Date 1996 05 10 Install 914 F Blank page ...

Page 61: ...Reference Modification No 0 Page 61 Date 1996 05 10 Install 914 F Blank page ...

Page 66: ...Reference Modification No 0 Page 66 Date 1996 05 10 Install 914 F Blank page ...

Page 71: ...Reference Modification No 0 Page 71 Date 1996 05 10 Install 914 F Blank page ...

Page 83: ...Reference Modification No 0 Page 83 Date 1996 05 10 Install 914 F Blank page ...

Page 102: ...Reference Modification No 0 Page 102 Date 1996 05 10 Install 914 F Leerseite ...