ROPV R80 S Series Manual

August

2005B

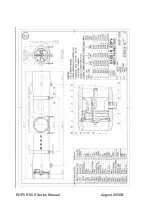

Head Installation

Step 1 Follow All Steps Outlined in the Head Reassembly Section

Step 2 Install Head

– Hold the head assembly with both hands, square to the axis of

the vessel. Push firmly with both hands until the head is correctly positioned and the

retaining groove is visible. It may be necessary to use a rubber mallet to tap the head

into its engaged position. The thrust cone must be installed with the head at the

downstream end of the vessel.

Step 3 Install Locking Kit Segments

– Clean and dry the retaining groove. Position

the first two locking segments (No.1 and No.2 in picture) so that the end section sits in

the retaining groove. Position the third locking segment (No.3) into the last area.

Position the securing ring as shown and use an M6 / 7/32” hex wrench to tighten the

screw until snug. Do not over-tighten – maximum torque guideline: 10Nm. Install the

two other segments in the same manner. Conduct a final tightness check of each screw

after all three segments are installed.

Step 4 Reconnect Permeate Piping

– Reconnect the system permeate piping to the

permeate port.

Step 5 Conduct Pre-Pressurization Inspection

– A thorough pre-pressurization

inspection should be conducted, including verifying that the heads are properly installed,

system piping connections are in place, elements are installed, adapters are installed,

and thrust cone is installed at downstream end of the vessel.

Locking Kit Segment

and Securing Ring