22

2

After welding machine is

over-heat, the fan doesn’t

work

Fan damaged

Change it

The cable is loosen

Screw the cable tightly

3

Press the

gun switch,

no output

shielded

gas

No output

gas when

test gas

No gas in the gas cylinder

Change it

Gas pipe leaks gas

Change it

Electromagnetic valve

damaged

Change it

Output gas

when test

gas

Control switch damaged

Repair the switch

Control circuit damaged

Check the board

4

Wire-

feeder

doesn’t

work

Wire reel

doesn’t

work

Motor damaged

Check and change it

Control circuit damaged

Check the board

Wire reel

works

The press wheel is loosen

or weld wire skids

Press it tightly again

The wheel doesn’t fit with

the diameter of weld wire

Change the wheel

Wire reel damaged

Change it

Wire feed pipe is jammed

Repair or change it

Tip is jammed because of

splash

Repair or change it

5

No striking arc and no

output voltage

Output cable is connected

mistakenly, or loosen

Screw it down or change it

Control circuit damaged

Check the circuit

6

Welding stops, and alarm

light is on

Machine has self-

protection

Check over-voltage, over-current,

over-temperature, lower-voltage and

over-temperature, and solve it

7

Welding current is run

away and can be not

controlled

The potentiometer

damaged

Check or change it

The control circuit

damaged

Check the circuit

8

The crater current can be

not adjusted

The PCB damaged

Check it

9

No post-gas

The PCB damaged

Check it

Summary of Contents for 250MIG

Page 1: ...SERIES 250MIG MIG ...

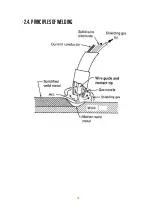

Page 10: ...10 2 4 Principles of welding ...

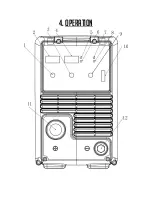

Page 16: ...16 4 OPERATION ...

Page 23: ...23 5 3 ELECTRICAL SCHEMATIC DRAWING ...

Page 24: ...24 250MIG MIG ...