3. Assembling and Installing

18

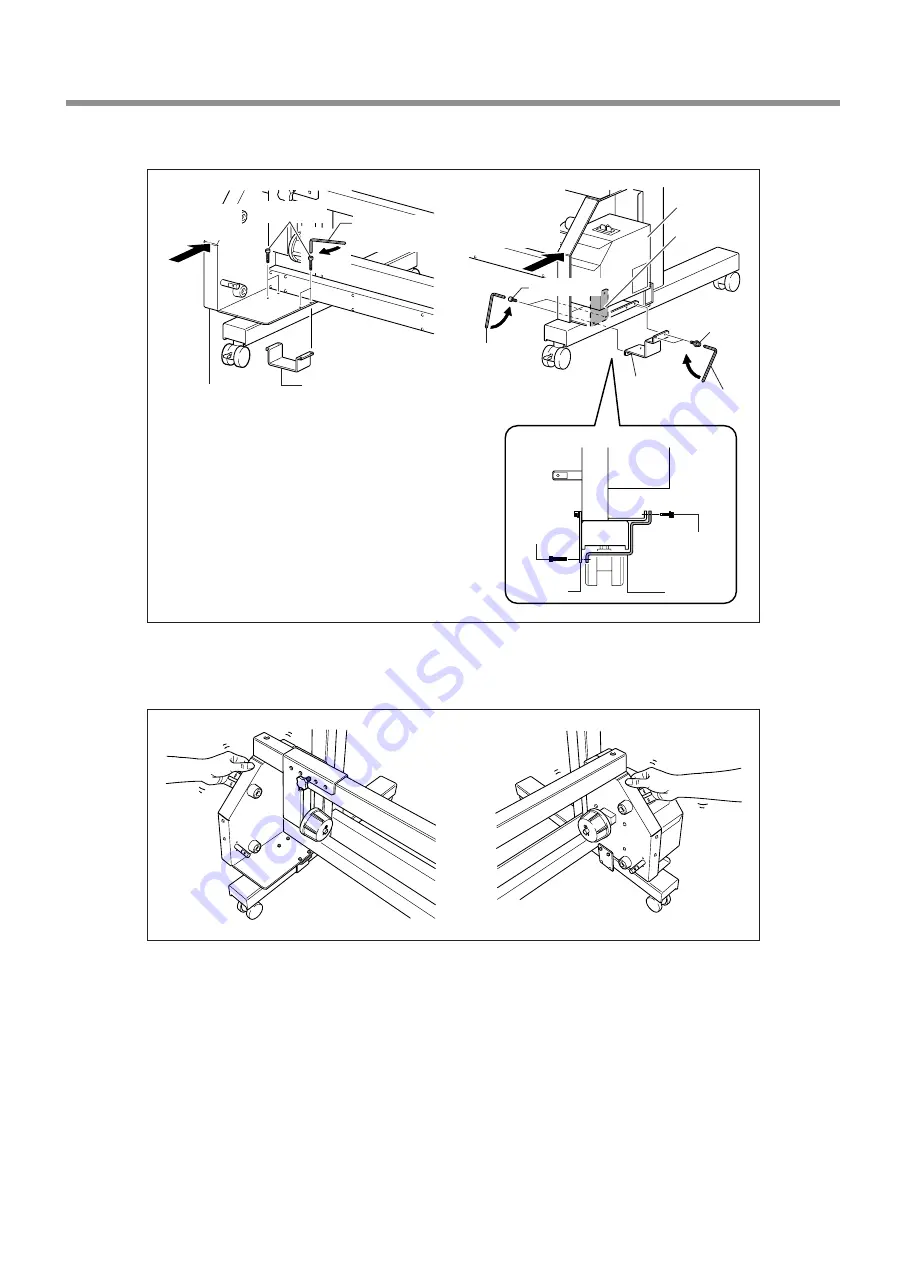

Other Models (VS series, RS series, VP series, SP-300V/300, SP-540i/300i, RA-640, RE-640 etc.)

After securing in place, hold the unit at the locations shown in the figure, apply gentle pressure, and make sure the

assembly is free of looseness. If looseness is present, again press the take-up unit against the stand leg and caster

and tighten the small bolts.

Frame

Small bolts

Control box

Press against

the stand leg.

Hex wrench

(small)

Press against

the stand leg.

Hex wrench

(small)

Mounting fixture C

Hex wrench

(small)

Mounting

fixture A

Mounting

fixture B

Bolts with

washer

Small bolts

Mounting

fixture A

Mounting

fixture B

Small bolt

Bolt with

washer