29

Load a material, then close the front cover.

1

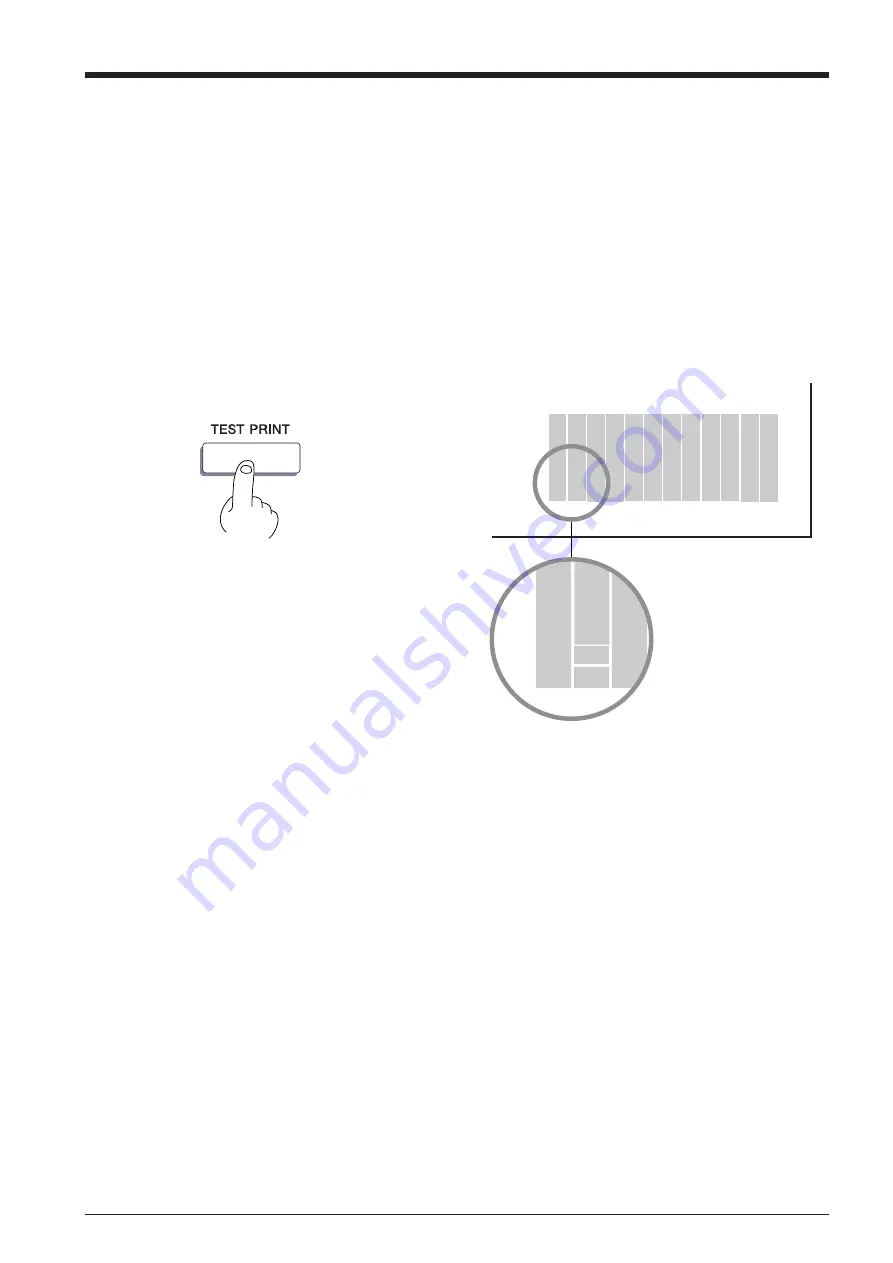

Hold down the [TEST PRINT] key for 1 second or longer to execute [TEST PRINT].

2

If there are any missing dots or other evidence

of a drop in printing quality, clean the head

(see "Maintenance -- Cleaning the Printing

Heads").

2 Test Printing

Printing quality is greatly affected by the state of the printing heads.

Before starting to print, you can carry out a printing test to check the state of the printing heads.

If the printing heads are in a poor state and problems such as dot drop-out occur, printing quality drops.

If the test results show a problem, carry out head cleaning to restore the head to its normal state.

Setup for Printing

Summary of Contents for SOLJET SC-500

Page 14: ...12 MEMO...

Page 56: ...54 Maintenance MEMO...

Page 78: ...76 User s Reference MEMO...

Page 99: ...R1 011011...