27

Press the [SETUP] key. This detects the width of the

material and shows the printable width on the display.

*When [EDGE] is selected in step 9, the width of

the loaded material is detected, then the front

edge of the material is aligned with the print-start

location.

10

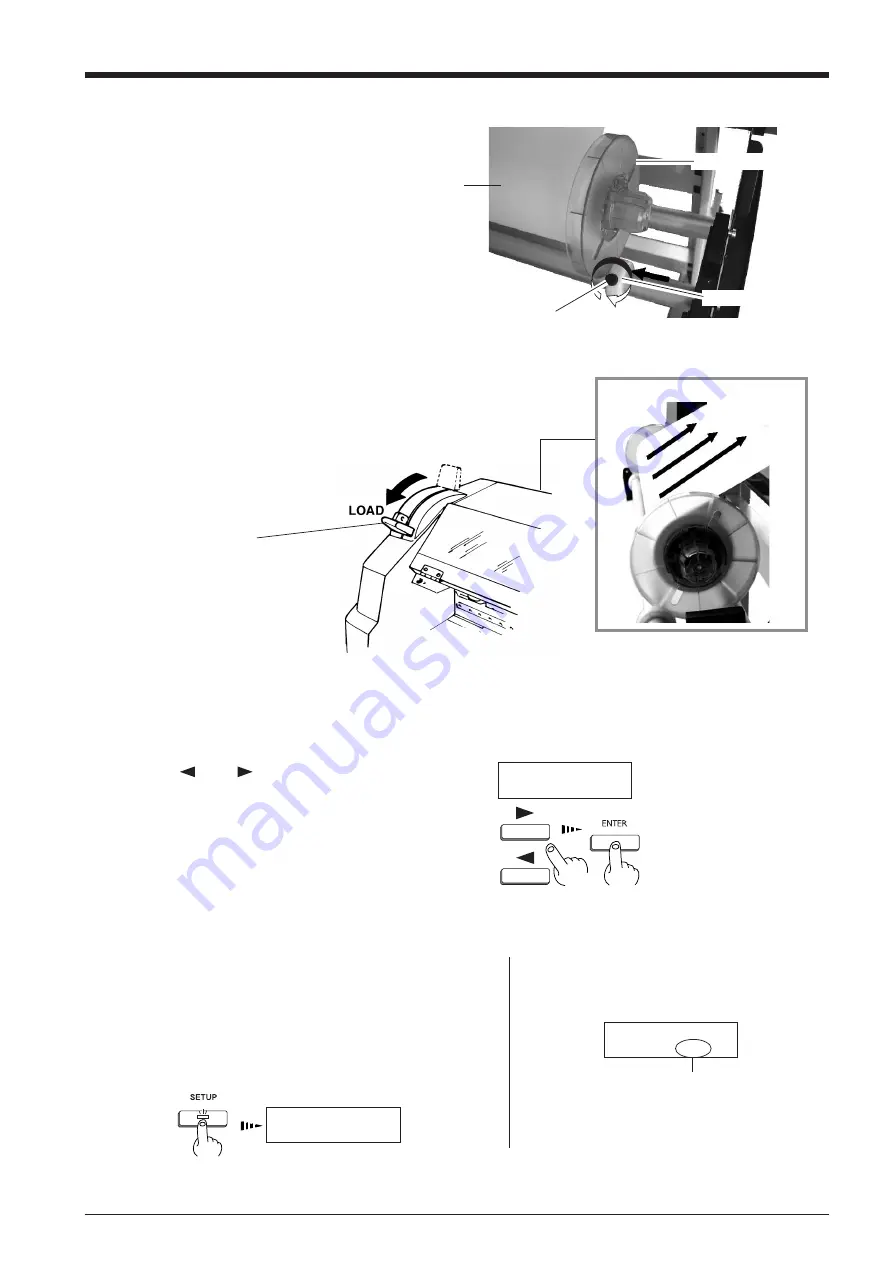

Align the left- and right-hand stoppers with the width

of the material and tighten the screws to secure in

place.

7

Rear

Close the front cover.

Use the [

] and [

] keys to select [ROLL], then

press the [ENTER] key.

*If printing is to be performed from the edge of

the material, select [EDGE] (If [EDGE] does not

appear, set [EDGE SENSE] to [ENABLE]).

9

Top menu

W1000mm L ---mm

FINE BI-DIR

The SETUP LED lights up

If a pinch roller is positioned over an area where is no

grit roller, the massage shown at below appears when

you press the [SETUP] key.

SETUP SHEET

ROLL EDGE PIECE

PINCHROLL ERROR

INVALID LEFTPOS

or [RIGHT]

Setup for Printing

Check the positioning of the pinch rollers and make

sure they are aligned at the correct positions.

From the front of the unit, pull the center of material

straight out toward the front. Without letting any part

of the entire piece of material pulled out to become

slack, move the sheet loading lever all the way to

“LOAD.”

The pinch rollers lower to hold the material in place.

8

Rear

Entire material

stretched taut

* If there is slackness in the loaded

material, the material may move at

an angle and come loose from the

pinch rollers.

Screw

Stopper

Media flange

Roll material

Sheet loading lever

When moved partway, only the

right-hand pinch roller descends.

Data cannot be output while in this

state. To secure the material in

place, move all the way to

"LOAD."

Summary of Contents for SOLJET SC-500

Page 14: ...12 MEMO...

Page 56: ...54 Maintenance MEMO...

Page 78: ...76 User s Reference MEMO...

Page 99: ...R1 011011...