6-1 What to Do If

Chapter 6 Appendix

83

the image is unrelated to the printing location, such as when

uneven areas vary from one piece of material or image to

another. We recommend using a head cap whenever such

use is possible.

☞

P. 27 "Head Caps"

Procedure

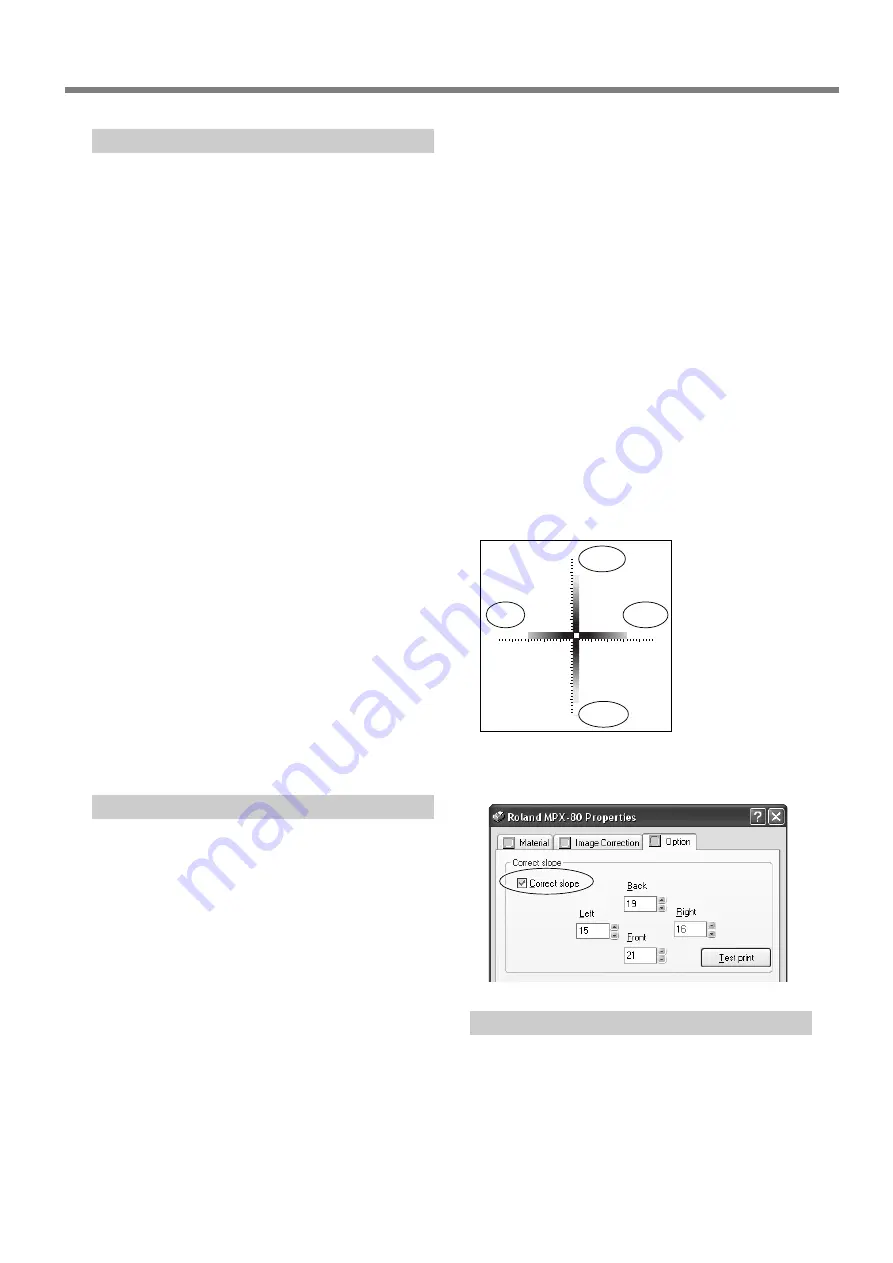

1. Using an adhesive sheet, load a piece of included test-

use printing material at the center of the table.

If the included material has been used up, then prepare a

piece of material that is larger than 60 mm (2.3 in.) and has

a smoothness of 0.05 mm (0.002 in.) or less.

☞

P. 31, "Loading Material Using the Adhesive Sheet"

2. Go into the [Printers] folder. Right-click the [Roland MPX-

80] and open the setting screen for the METAZA driver.

Click [Printing Preferences].

3. Click the [Option] tab.

4. Click [Test print].

The test pattern is printed on the material.

5. Use the scale to read and note down locations where the

test pattern is not continuous or not visible. Note down the

values in all four directions (front, back, left, and right).

6. Select [Correct slope] and enter the scale values you noted

into the driver.

The printed location isn't where desired

The center of the table scale may not coincide with the

machine's printing origin point.

To correct displacement between the scale center and the

printing origin point.

☞

P. 76, "Adjusting the Location of the Machine's Origin Point"

The image is uneven.

Is the printed surface slightly uneven?

If no head cap is attached, then attach a head cap and per-

form printing. If you’re using material that can be damaged

by printing with the head cap attached, then replace it with

material that has a level printing surface.

☞

P. 27, "Head Caps", p. 28, "Preparing Material to Print"

Is the printed surface at an angle?

If no head cap is attached, then attach a head cap and per-

form printing. If you’re using material that can be damaged

by printing with the head cap attached, then replace it with

material that has a level printing surface.

☞

P. 27, "Head Caps", p. 28, "Preparing Material to Print"

Is the image darkness uneven?

Performing overstriking with the material left loaded at the

same location may improve the image quality. Try perform-

ing overstriking with different settings for [Gamma], [Bright-

ness], or [Contrast] in the driver's setting window.

☞

P. 64, "Driver Settings", driver online help "[Correction] tab"

Was bidirectional printing performed?

Bidirectional printing can shorten the printing time, but the

image quality may suffer. If this happens, go to the driver's

setting window and clear the selection for [Bidirection],

then redo printing.

☞

P. 64, "Driver Settings", driver online help "[Material] tab"

Is the marking pin worn?

Attractive printing may be impossible if the marking pin

becomes worn.

Adjust the pin or change it to a new one.

☞

P. 70, "Maintenance of the Head and the Marking Pins"

The image is always faint at the same location.

If you’re using a head cap

If the image is always faint at the same location even though

you’re performing printing using a head cap, the height dis-

placement for the printed surface may be excessive. Re-

check the parameters of materials that the machine can print

and select material that meets the parameters. Also, image

quality is not assured when printing photographic data on

a curved surface with this machine.

☞

P. 28 "Preparing Material to Print"

If you’re not using a head cap

If the image is often faint at the same location, such

as near the front right area of the table, then adjust-

ing the levelness of the machine may improve the

image quality.

Please note that this is not effective when unevenness in

5

10

10

15

15

20

20

5

5

5

10

15

20

10

15

20

Right

Left

Back

Front

Summary of Contents for Metaza MPX-80

Page 12: ...10 ...

Page 13: ...11 Chapter 1 Getting Started ...

Page 18: ...16 ...

Page 19: ...17 Chapter 2 Getting Ready to Print ...

Page 25: ...23 Chapter 3 Performing Printing ...

Page 45: ...43 Chapter 4 More Advanced Operations ...

Page 69: ...67 Chapter 5 Maintenance and Adjustment ...

Page 82: ...80 ...

Page 83: ...81 Chapter 6 Appendix ...

Page 91: ...89 ...

Page 92: ...90 ...

Page 93: ...91 ...

Page 94: ...92 ...

Page 95: ...93 ...

Page 96: ...94 ...

Page 97: ...95 ...

Page 98: ...96 ...

Page 99: ......

Page 100: ...R1 070820 ...