3-8 Starting Printing

Chapter 3 Performing Printing

42

Stopping Printing Operations

Procedure

➊

Switch off the power.

☞

P. 24, "Switching Off the Power"

➋

Windows Vista

Click [Start], then click [Control Panel].

Click [Hardware and Sound], then click [Printers].

Windows XP

Click [Start], then click [Control Panel].

Click [Printers and Other Hardware], then click [Printers and Faxes].

Windows 2000

Click [Start].

Click [Settings], then click [Printers].

➌

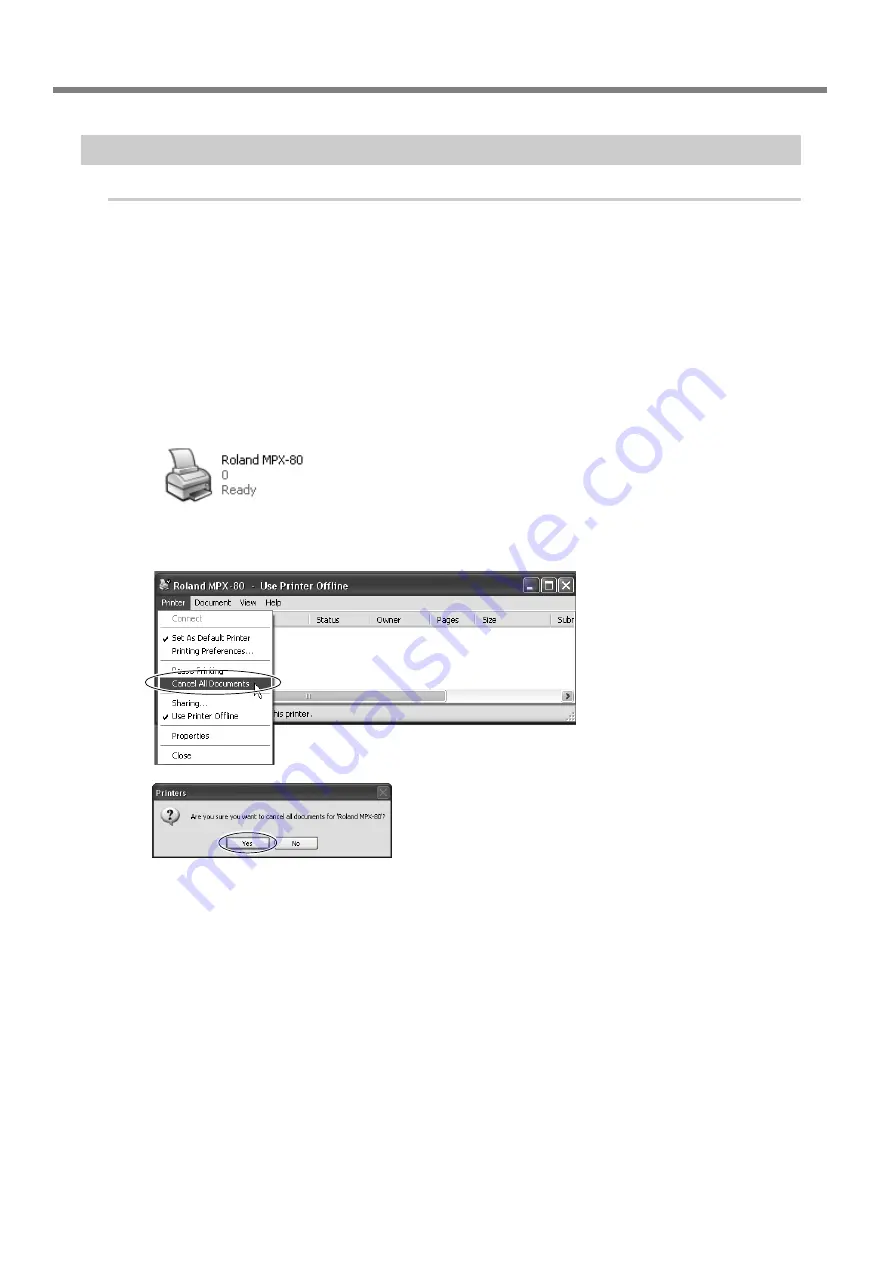

Double-click the [Roland MPX-80] icon.

➍

At the [Printers] menu, click [Cancel All Documents] (or [Purge Print Documents]).

➎

If the message shown in the figure appears, click

“Yes.”

Summary of Contents for Metaza MPX-80

Page 12: ...10 ...

Page 13: ...11 Chapter 1 Getting Started ...

Page 18: ...16 ...

Page 19: ...17 Chapter 2 Getting Ready to Print ...

Page 25: ...23 Chapter 3 Performing Printing ...

Page 45: ...43 Chapter 4 More Advanced Operations ...

Page 69: ...67 Chapter 5 Maintenance and Adjustment ...

Page 82: ...80 ...

Page 83: ...81 Chapter 6 Appendix ...

Page 91: ...89 ...

Page 92: ...90 ...

Page 93: ...91 ...

Page 94: ...92 ...

Page 95: ...93 ...

Page 96: ...94 ...

Page 97: ...95 ...

Page 98: ...96 ...

Page 99: ......

Page 100: ...R1 070820 ...