Periodic examination

34

All autoclaves should be examined at least once in

every 26 months by a person who is competent to assess

their suitability for continued safe use. If shorter intervals are

set under the relevant legislation, then those intervals should

be used. Examination of autoclaves should take account of

their mechanical strength, as influenced by, and the effects of,

wear, damage, corrosion, erosion etc. Special attention

should be paid to the correct functioning of all safety devices,

safety interlocks and fittings.

Routine maintenance

35

At regular intervals, determined by the conditions of

operation and the manufacturer's instructions, the whole

system should be checked by an experienced person

properly trained and competent to recognise defects. Checks

should follow written procedures which take account of the

manufacturer's instructions, any special factors relating to the

particular use of the autoclave, and frequency of operation.

Particular attention should be paid to the correct functioning of

all safety devices and interlocks, and it is recommended that

the experienced person checks these items at the beginning

of each shift when the autoclave is in use. Any faults or

defects which affect the safety of the vessel should be

promptly reported to an appointed superior who will ensure

that the autoclave is not used until the fault has been rectified.

Comprehensive records of examinations, tests, faults, repairs

and modifications should be maintained and entries should be

countersigned by a responsible member of management.

Manufacturers maintenance instructions should be strictly

adhered to.

LEGAL

36

The general requirements of the Health and Safety at

Work etc Act 1974 (HSW Act) apply to all autoclaves. These

require good design, construction and maintenance of the

plant together with provision of a safe system of work and

properly trained operators, maintenance staff and

supervision. The aim is to secure, so far as is reasonably

practicable the health and safety of employees,

self-employed persons and others who may be affected by a

work activity.

37

The Factories Act 1961 Section 30 may apply, see

HSE Guidance Note GS5 -

Entry into confined spaces.

38

The Pressure Systems and Transportable Gas

Container Regulations 1989 replace sections of the

Factories Act 1961 covering steam boilers, steam and air

receivers from 1 July 1990 with transitional provisions.

Requirements are laid down for the design, construction,

repair, installation, periodic examination in accordance with

a written scheme, operation, maintenance and keeping of

records. The Regulations apply across-the-board

provisions to all workplaces, with specific exceptions, and

are intended to prevent risk of injury from unintentional

releases of stored energy from pressure systems which

contain a 'relevant fluid' as defined in the Regulations.

Essentially 'relevant fluid' means gas and fluids under

pressure, including air and hot water kept above its boiling

point, at a pressure greater than 0.5 bar. In addition

'relevant fluid' covers steam at any pressure.

39

This Guidance Note gives advice which is

complementary to the Approved Codes of Practice and

Guidance which accompany the Regulations.

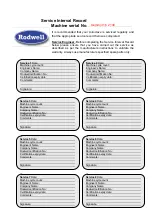

FURTHER INFORMATION

This Guidance Note is published by HMSO. Further advice

on this or any other publications produced by the Executive is

obtainable from HSE's Information Centres:

Health and Safety Executive

Library and Information Services

Broad Lane

SHEFFIELD S3 7HO

Tel: 0742 752392 Telex: 54556

Health and Safety Executive

Library and Information Services

St Hugh's House

Stanley Precinct

Trinity Road

BOOTLE

Merseyside L20 30Y

Tel: 051-9514381 Telex: 628235

Health and Safety Executive

Library and Information Services

Baynards House

1 Chepstow Place

Westbourne Grove

LONDON W2 4TF

Tel: 071-221 0416 Telex: 25683 or

from Area Offices of the HSE.

BIBLIOGRAPHY

BS 470:

Inspection, access and entry openings for

pressure vessels.

BS 1746:

Specification for domestic pressure cookers.

BS 2646:

Autoclaves for sterilization in laboratories.

BS 3970:

Autoclaves for sterilizing and disinfecting

medical products.

BS 5304:

Safety of machinery.

BS 5500:

Unfired fusion welded pressure vessels.

HSE Guidance Note GS4

Safety in pressure testing.

HMSO ISBN 0 11 883043 0

HSE Guidance Note GS5

Entry into confined spaces.

HMSO ISBN 0 11 883067 8