8

MP-Series Food Grade Servo Motor Installation Instructions

Publication MP-IN004D-EN-P — April 2009

Install the Motor

All motors include a mounting pilot for aligning the motor on the machine.

Preferred fasteners are stainless steel. The installation must comply with all local

regulations and use equipment and installation practices that promote safety and

electromagnetic compatibility.

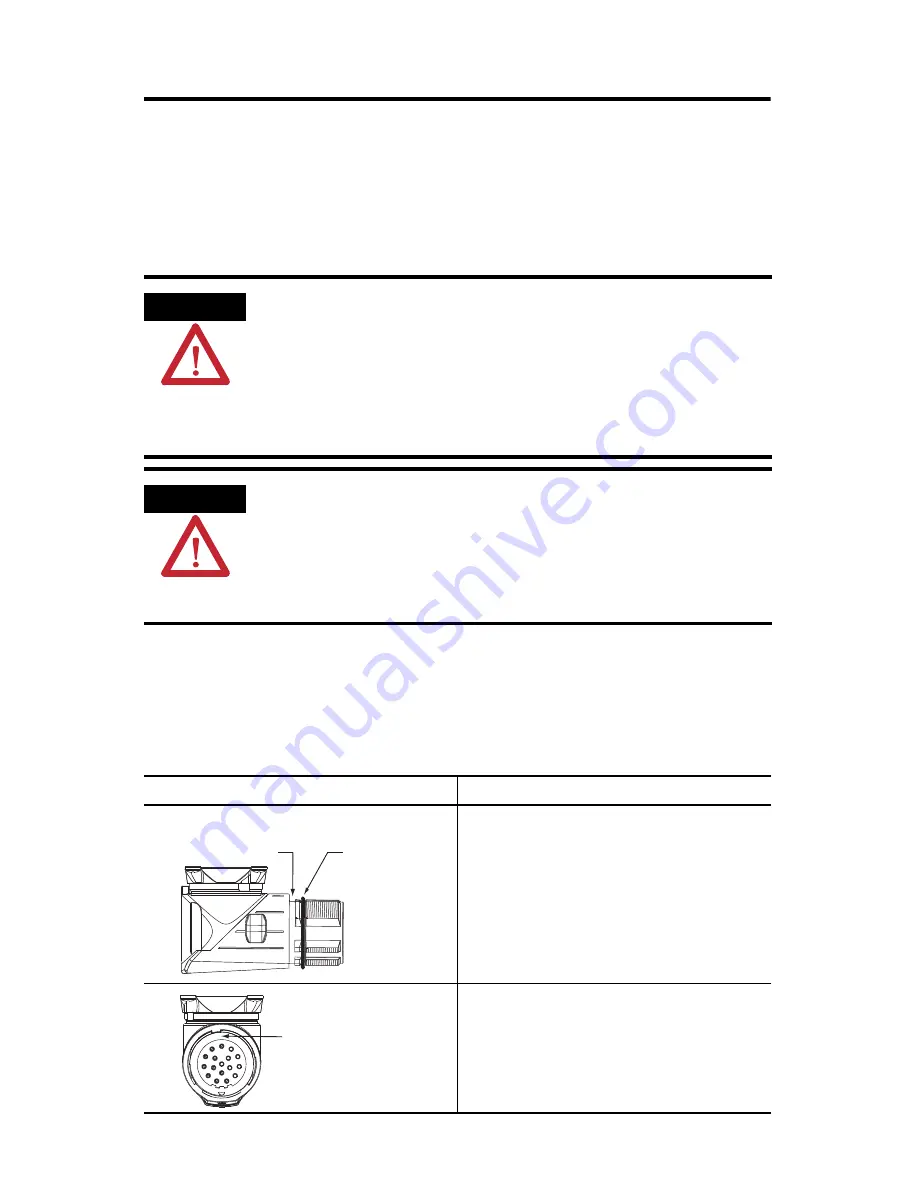

Verify Connector O-ring and Backshell Seal

O-rings on the feedback and motor/brake connectors secure cable plugs, and a

backshell seal on the feedback connector is necessary to achieve the maximum

environmental rating. Verify the seal and O-rings are installed as described.

ATTENTION

Unmounted motors, disconnected mechanical couplings, loose shaft keys, and

disconnected cables are dangerous if power is applied.

Disassembled equipment should be appropriately identified (tagged-out) and access to

electrical power restricted (locked-out).

Before applying power to the motor, remove the shaft key and other mechanical couplings

which could be thrown from the shaft.

Failure to observe safety precautions could result in personal injury.

ATTENTION

Make sure that cables are installed and restrained to prevent uneven tension or flexing at

the cable connections.

Excessive and uneven lateral force on the cable can result in the environmental seal

opening and closing as the cable flexes.

Failure to observe safety precautions could result in damage to the motor and its

components.

Location Verify

•

An O-ring is mounted on the external surface of

both the power/brake connector and the

feedback connector.

•

The O-ring is undamaged, not twisted, and rests

in the groove as shown in the illustration.

•

A backshell seal covers the joint between the

backshell and the connector housing.

•

The backshell seal is undamaged, and it is fully

seated against the face of the backshell.

O-ring On Both

Connector

Housings

Groove Reserved For

Quick-lock Plug

Backshell Seal Inside

Feedback Connector

Housing