Rockwell Automation Publication GMC-RM002F-EN-P - June 2013

29

Appendix

A

Specifications

This chapter provides safe torque-off feature specifications for your Kinetix 6000

and Kinetix 7000 drives.

Safe Torque-off Response

Time Specifications

The system reaction time is the amount of time from a safety-related event as

input to the system until the system is in the safe state. Faults within the system

can also have an effect upon the reaction time of the system. The safe torque-off

response time for the Kinetix 6000 and Kinetix 7000 safe torque-off drives is

25 ms. This is the time from change of state at the drive input to change of state at

the drive output.

Safe Torque-off Signal

Specifications

To maintain safety rating, Kinetix 6000 and Kinetix 7000 drives must be

installed inside protected control panels or cabinets appropriate for the

environmental conditions of the industrial location. The protection class of the

panel or cabinet should be IP54 or higher.

Kinetix 6000 (series A and B) and Kinetix 7000 Servo Drives

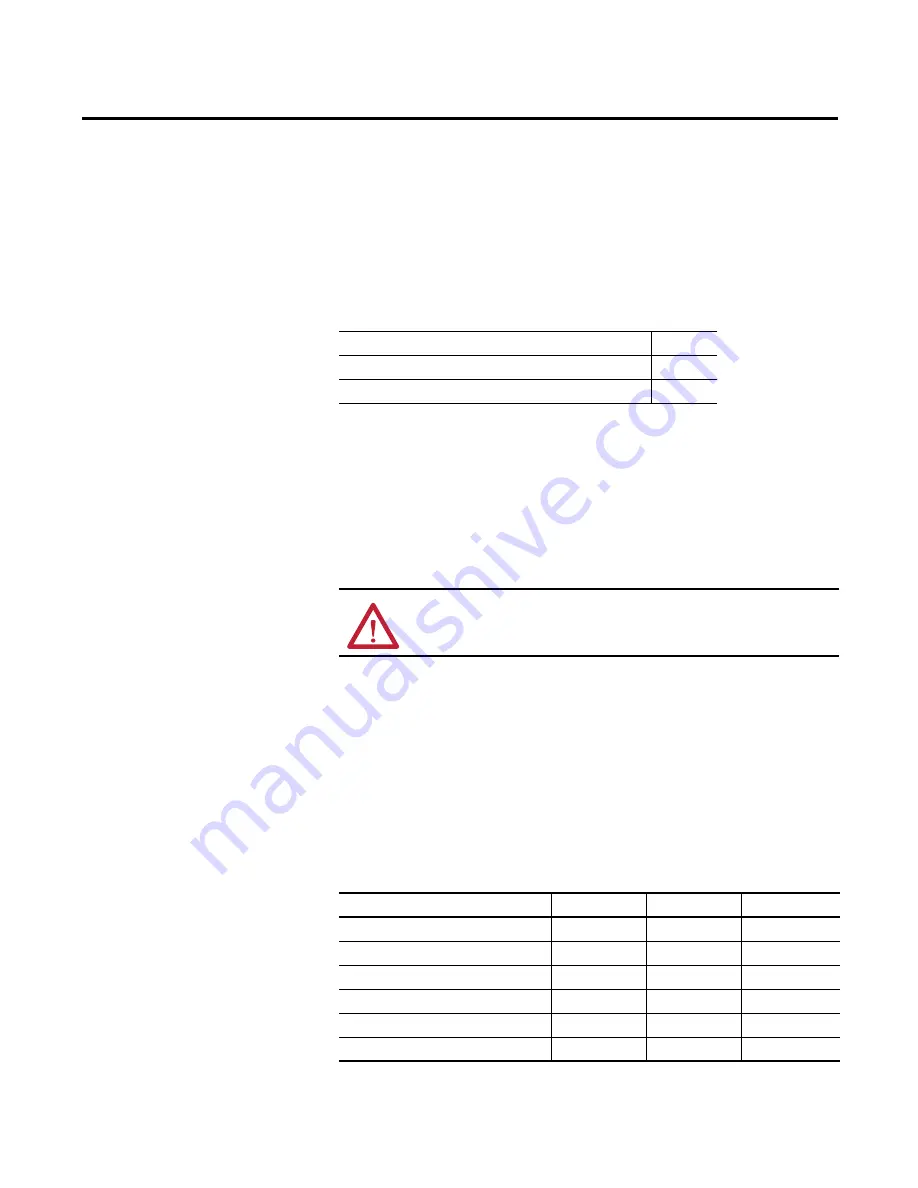

Table 8 - Relay Coil Specifications for the ENABE Signals

Topic

Page

Safe Torque-off Response Time Specifications

Safe Torque-off Signal Specifications

ATTENTION:

The safe torque-off response time is typical of drive performance.

Actual system response time will vary depending on your application.

Attribute

Nom

Min

Max

Pull-in Voltage

24V

18V

26.4V

Drop-out Voltage

—

0V

2.4V

Coil Resistance

720

Ω

648

Ω

792

Ω

Coil Current

33.3 mA

—

55.0 mA

Pull-in Time

25 ms

—

—

Drop-out Time

20 ms

—

—