SECTION 14: R

EPLACEMENT

P

ARTS

33

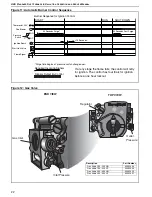

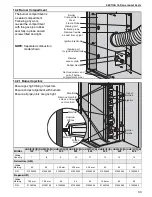

14.2 Burner Compartment

14.2.1 Burner Injectors

MODEL

UHD[X][S][R]

150

UHD[X][S][R]

175

UHD[X][S][R]

200

UHD[X][S][R]

225

UHD[X][S][R]

250

UHD[X][S][R]

300

UHD[X][S][R]

350

UHD[X][S][R]

400

Orifice

Quantity

7

8

9

10

11

12

14

14

Natural Gas (G20)

Orifice

Marking

43

43

2.25 mm

2.25 mm

2.25 mm

40

40

40

P/N

91930043

91930043

91930225

91930225

91930225

91930040

91930040

91930040

Propane (G31)

Orifice

Marking

1.35 mm

1.35 mm

54

54

54

1.45 mm

53

53

P/N

91930135

91930135

91930054

91930054

91930054

91930145

91930053

91930053

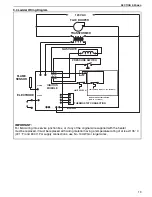

Remo

v

e flexi

b

le

air d

u

ct from spigot

Remo

v

e

access plate

Remo

v

e scre

w

s and

p

u

ll off

bu

rner

compartment co

v

er

V

ie

w

ing port

for flame pro

b

e

V

ie

w

ing port

for ignition electrode

Flame Pro

b

e

B

u

rner

Compartment

Co

v

er

R

ubb

er Seal

Ignition Electrode

The burner compartment is

a sealed compartment.

Following any work,

re-seal the compartment

with the gas pipe rubber

seal fully in place and all

screws fitted and tight.

NOTE:

Separated combustion

model shown.

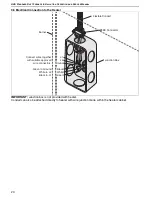

Remo

v

e manifold

scre

w

s and p

u

ll

o

u

t manifold

Manifold

Inshot

B

u

rners

Injectors

B

u

rner

Scre

w

s

B

u

rner

v

ent

u

ri

Unscrew

Orfices

Manifold

Marking

Folded

Hem

Ensure gas tight fitting of injectors.

Ensure correct alignment with burners.

Ensure all pipe joints are gas tight.