Übersicht über die Baustufen

Seite

Baustufe 1: Vormontage Chassis

4, 5

Baustufe 2: Vorderachse

6-9

Baustufe 3: Hinterachse

10-13

Baustufe 4: Montage Karosserie- und Motorhalter

14, 15

Baustufe 5: Antrieb

16, 17

Baustufe 6: Kotflügel und Rückleuchten

18, 19

Baustufe 7: Funktionsprobe der RC-Einbauteile

20, 21

Baustufe 8: Anbauteile am Chassis

22-25

Baustufe 9: Zusammenbau Fahrerhaus, Tank

26, 27

Baustufe 10: Innenausbau Fahrerhaus

28, 29

Baustufe 11: RC-Einbau, Montage Fahrerhaus,

30-33

Abschließende Arbeiten

Baustufe 12: Die Kippmulde

34-37

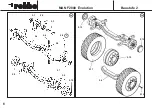

Baustufe 1:

Vormontage Chassis

Pos.-Nr.

Bezeichnung

Maße (mm)

Anzahl

1.1

Leiterrahmen

1

1.2

Blattfeder, vorn

2

1.3

Blattfeder, hinten rechts

1

1.4

Blattfeder, hinten links

1

1.5

Blattfederhalter

8

1.6

Zylinderschraube

M3 x 16

8

1.7

U-Scheibe

ø 3,2 innen

8

Montage der Blattfedern (Pos. 1.1 - 1.7)

-

Blattfedern 1.2 (vorne) mit Blattfederhaltern 1.5 sowie

Blattfedern hinten 1.3 - 1.4 mit Blattfederhaltern 1.5 mit

Zylinderschrauben 1.6 und Unterlegscheiben 1.7 an

den Leiterrahmen 1.1 schrauben

HINWEIS:

Auf die richtige Seitenzuordnung der hinteren

Blattfedern achten!

Zylinderschrauben 1.6 mit flüssigem

Schraubensicherungsmittel sichern!

Summary of Stages of construction

page

Stage 1: Initial chassis assembly

4, 5

Stage 2: Front axle

6-9

Stage 3: Rear axle

10-13

Stage 4: Bodywork holder and motor mount

14, 15

Stage 5: Power system

16, 17

Stage 6: Mudguards and rear light clusters

18, 19

Stage 7: Checking the RC installation components 20, 21

Stage 8: External chassis fittings

22-25

Stage 9: Assembling the driver’s cab and fueltank

26, 27

Stage 10: Internal driver’s cab fittings

28, 29

Stage 11: RC installation, installing the driver’s cab, 30-33

final work

Stage 12: The tipper body

34-37

Stage 1:

Initial chassis assembly

Part No.

Description

Size (mm)

No. off

1.1

Ladder frame

1

1.2

Front leaf spring

2

1.3

Rear R.H. leaf spring

1

1.4

Rear L.H. leaf spring

1

1.5

Leaf spring holder

8

1.6

Cheesehead screw

M3 x 16

8

1.7

Washer

3.2 I.D.

8

Fitting the leaf springs (parts 1.1 - 1.7)

-

Fix the front leaf springs 1.2 and the rear leaf springs

1.3 - 1.4 to the ladder frame 1.1 using the leaf spring

holders 1.5, cheesehead screws 1.6 and washers 1.7.

NOTE:

Note that the rear leaf springs are handed (different

right and left). Secure the cheesehead screws 1.6 with

thread-lock fluid.

Vue d’ensemble de stades de construction

page

Stade 1:

montage préliminaire du châssis

4, 5

Stade 2:

montage préliminaire du châssis

6-9

Stade 3:

essieu arrière

10-13

Stade 4:

support-carrosserie et support-moteur

14, 15

Stade 5:

entraînement

16, 17

Stade 6:

garde boues et feux arrière

18, 19

Stade 7:

essai de fonctionnement des

20, 21

éléments de l’ensemble de réception

Stade 8:

aménagement du châssis

22-25

Stade 9:

assemblage de la cabine

26, 27

Stade 10: aménagement intérieur de la cabine

28, 29

Stade 11: montage de l’ensemble de réception

30-33

montage de la cabine, travaux de finition

Stade 12: montage de la benne

34-37

Stade 1:

montage préliminaire du châssis

n°

désignation

cotes (mm)

nbre

1.1

châssis

1

1.2

ressort à lames, avant

2

1.3

ressort à lame arrière droit

1

1.4

ressort à lame arrière gauche

1

1.5

support de ressort à lame

8

1.6

vis à tête cylindrique

M 3 x 16

8

1.7

rondelle

ø 3,2 intér.

8

Montage des ressort à lame (n° 1.1 à 1.7)

-

Visser les ressorts à lame 1.2 avant aux supports 1.5

et les ressorts à lame arrière 1.3-1.4 aux supports 1.5

avec les vis à tête cylindrique 1.6 et les rondelles 1.7

au châssis 1.1.

À NOTER:

veiller à la bonne disposition latérale des ressorts à

lame arrière! Freiner les vis à tête cylindrique 1.6 avec

un liquide spécifique !

MAN F2000

Evolution

Baustufe 1

5