11

KS3 DOOR

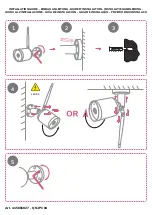

Step 3:

Remove the Door. Pre

-

drill and screw another 2 screws

between the centre screw and the rivets at each end (5

screws per track). Screw track using 45mm door track

screws.

Step 2:

Hang the door in the Door Track. At the right hand end of

Door Track, adjust up or down so that the Door hangs par-

allel with shed. Fit one rivet at right hand end to hold in

place. Repeat with left hand end of track.

Note: Only use rivets at each end of track.

Step 1:

Position the Door Track (107) on the front wall with the top

of the track 7mm below the top of the timber frame. The

left

-

hand end of the door track should be 20mm in from

left side of the left

-

hand door jamb flashing.

Pre

-

drill a hole in the centre of the track and screw in place

using one 45mm door track screw. Remove ALL drill filings

Note: Ensure Door Track screws are screwed in horizontal and

screwed hard into flashing. Protruding screw heads

can cause door rollers to bind on the screw heads.

KS3 DOOR

Step 5:

Bottom Door Guide: Slide the Door to open position. Place the

Door Guide (108) over the Guide Brackets on the door and align

the end of the Door Guide 20mm in from left side of the left

-

hand door jamb flashing.

Step 6:

Lift the door guide up approximately 3mm so that the Door will

Slide freely. Pre

-

drill a hole through the door guide and the end

rib of the cladding and screw in place using a 45mm screw.

Step7:

Slide the door to the centre, ensuring that it slides freely. Pre

-

drill and insert a screw in the other end of the Door Guide.

Check that the Door is not binding in the middle then pre

-

drill

and fix with 3 more screws, one in the centre of the guide and

the other 2 evenly spaced between (5 screws per guide) into

the door step flashing and rib.

Note:

For sheds with Raised Base Plate option the Door Step Flash-

ing will protrude down past the Bottom Plate.

Attach Door Guide with rivets.

DOOR

GUIDE

DOOR

CLADDING

BOT-

PLATE

GUIDE BRACKET

7mm

Step 4:

Clean out ALL drill filings. Also make sure the Wheels

are cleaned of drill filings. Re

-

hang Door.

Door Stops: Predrill a hole at the end of the right

-

hand

end of track, into rib of cladding.

Predrill hole in left

-

hand end of track, 45mm from outside of

door jamb.

(60mm for Security door option.)

Screw door stops in using 1 x Roofing screw per stop.