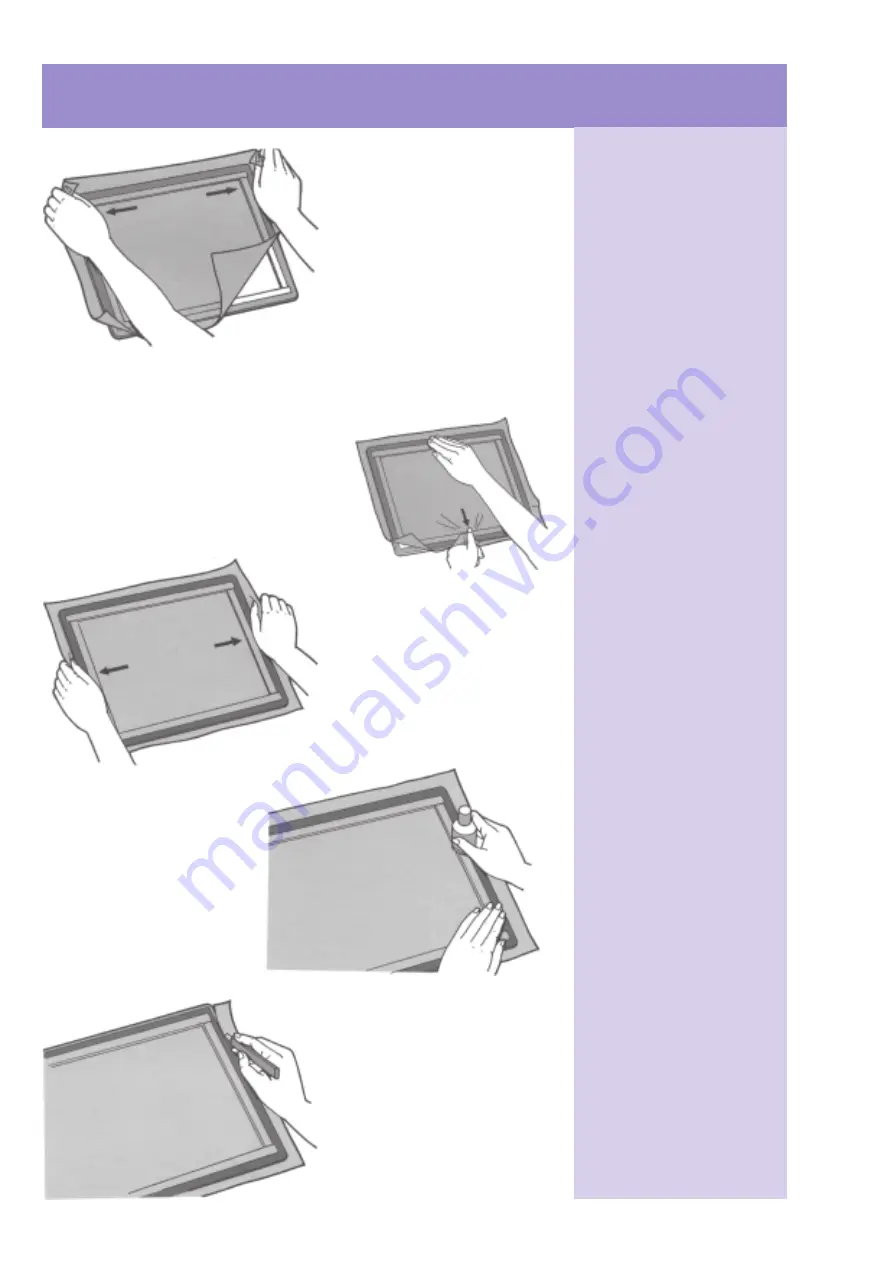

2. With the rough surface

facing down, attach the screen

to the frame. Start with one of

the two longer sides.

3. In the same way, fix the

middle of the opposite side, and

then attach the whole side while holding the

screen tight.

4. Now fix the two shorter sides, making

sure that you hold the screen

tight.

5. Once you have finished

attaching the screen so that

there are no wrinkles or slack in

the screen surface, rub the

edges with the bottom of a

correction fluid bottle or similar

hard object to make sure that

the screen is securely fixed.

6. Trim off any excess screen

around the outside of the frame.

l

When planning the size of the

screen, make it slightly larger than

the frame, as this will make mount-

ing easier.

l

Avoid over-stretching the screen -

you will not when this has been

done as plastic frame will bend

l

Do not use mechanical framing

devices

l

Over tension will reduce the print

life of the screen - remember the

mesh is already pre-tensioned

l

It is best to fix the middle first, then

start at one side and move to the

other.

l

Wrinkles or slack in the screen will

blur printed images.

l

Covering the trimmed areas with

tape will reinforce the screen.