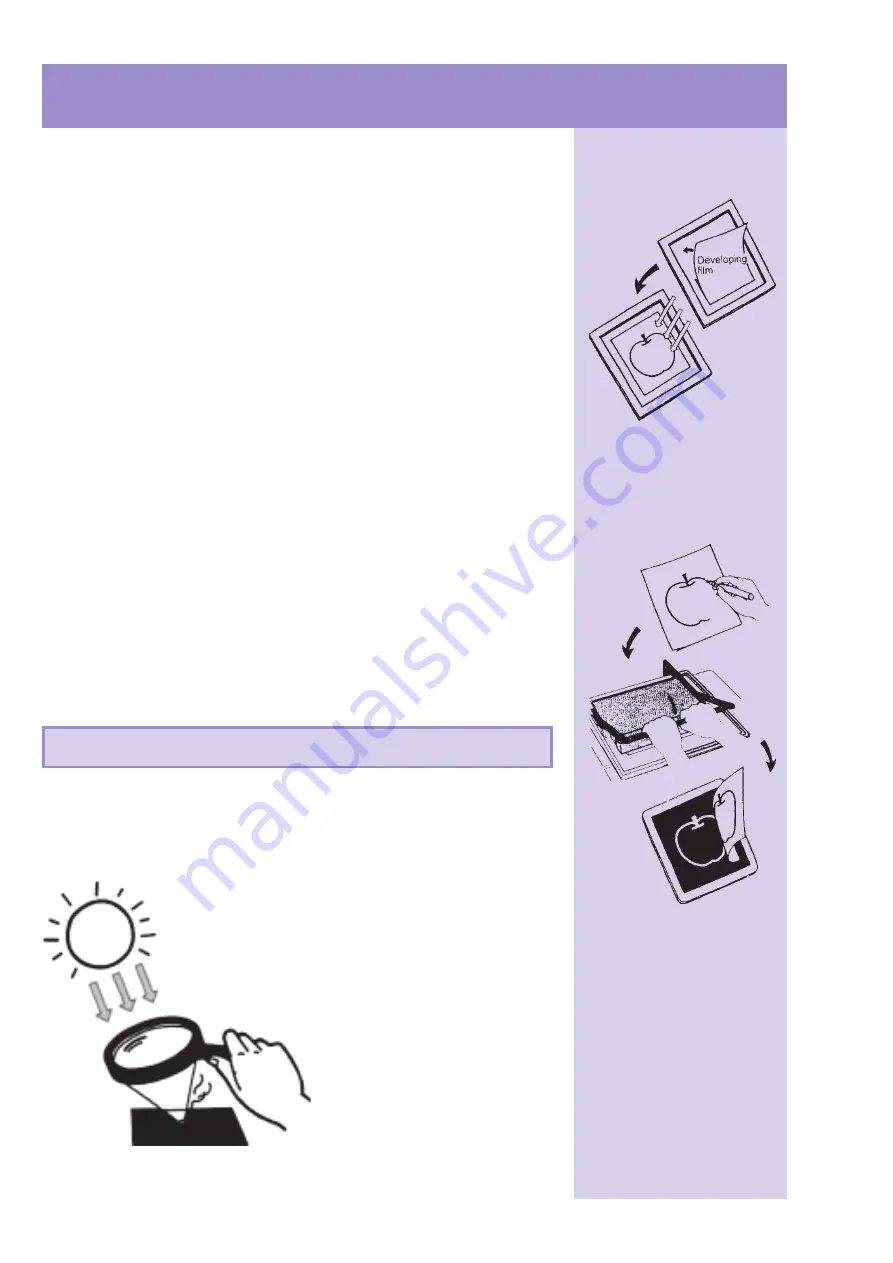

Combined Method

Features

Combines the screen durability of the direct method and the image sharp-

ness of the indirect method.

Procedures

1) Prepare film positive of the design.

2) Affix developing film to the screen.

3) Attach the film positive ad expose it.

4) Develop by bathing it in water.

Thermal Process

RISO Screen System

Features

Screen making is quick and easy. Preparing the original is also simple, and

there is no need to work with film positives.

Procedures

1) Draw the design using a carbon-containing writing implement.

2) Lay the design original on the screen and expose it to the flash.

3) Remove the design original.

If you were to draw a design in black on a piece of paper and

then focus a strong light on the paper using a magnifying glass,

small holes would be burned in the blackened sec-

tions. The RISO Screen System uses this prin-

ciple to create a screen master. The film sur-

face of RISO ScreenMasters will shrink rap-

idly if heat is applied. The carbon in the

ink used to draw the design reacts

with the infra-red light in the

flash, concentrating the

light’s heat. Minute holes

(which will allow ink to pass

when printing) are burned

into the screen in a pattern

matching the original design.

The principal behind the RISO Screen System

l

Combined Method

l

RISO Screen System