7

TECHNICAL SPECIFICATIONS

33 INSTALLATION AND REPAIR SHOULD

BE DONE BY A QUALIFIED SERVICE

PERSON. THE APPLIANCE SHOULD

BE INSPECTED BEFORE USE AND

AT LEAST ANNUALLY BY A

PROFESSIONAL SERVICE PERSON.

MORE FREQUENT CLEANING MAY

BE REQUIRED DUE TOO

EXCESSIVE LINT FROM CARPETING

BEDDING MATERIAL, ET CETERA. IT

IS IMPERATIVE THAT CONTROL

COMPARTMENTS, BURNERS AND

CIRCULATING AIR PASSAGEWAYS

OF THE APPLIANCE ARE KEPT

CLEAN.

34 The glass window shall be replaced as

one piece as supplied by the

manufacturer. See glass and log

installation on page 14

35 Do not substitute glass, glowing embers

or logs. Use only glass, glowing embers

and logs supplied by manufacturer.

36 Caution: Do not operate unit with broken

glass.

37 WARNING: DO NOT OPERATE

APPLIANCE WITH THE FRONT

REMOVED, CRACKED OR BROKEN.

REPLACEMENT OF THE GLASS

SHOULD BE DONE BY A LICENSED

OR QUALIFIED SERVICE PERSON.

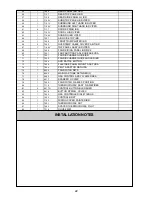

Natural Gas

Propane

Gas Input Rate:

Btu/hr

Btu/hr

Pilot:

200

200

13,000

11,000

High:

34,000

31,000

WC

WC

Min:

7"

10"

Max:

10.5"

13"

Gas Connection:

Flue Termination:

Fan:

Combustion System:

Logs:

Ceramic

Ignition System:

Operation:

Safety Devices:

Fan delay Bi-metal strip

Combustion Method:

Flue Type:

Heat transfer:

Installation Type:

Flue Requirement:

Minimum permissible

gas supply pressure

for purpose of input

adjustment

Manufacturers minimum, 10 ft vertical.

Local codes may have a greater

requirement and must be followed

Flame failure thermocouple

Over heat Bi-metal strip

Inbuilt

Naturally aspirated burner

B vent

Direct radiation and forced convection

3/8" MNPT

Push button to light pilot and main burners

An approved 4" vent cap must be fitted to all installations

90 Watt 2 speed tangential

Multi port burner

Continuous spark electronic ignition