22

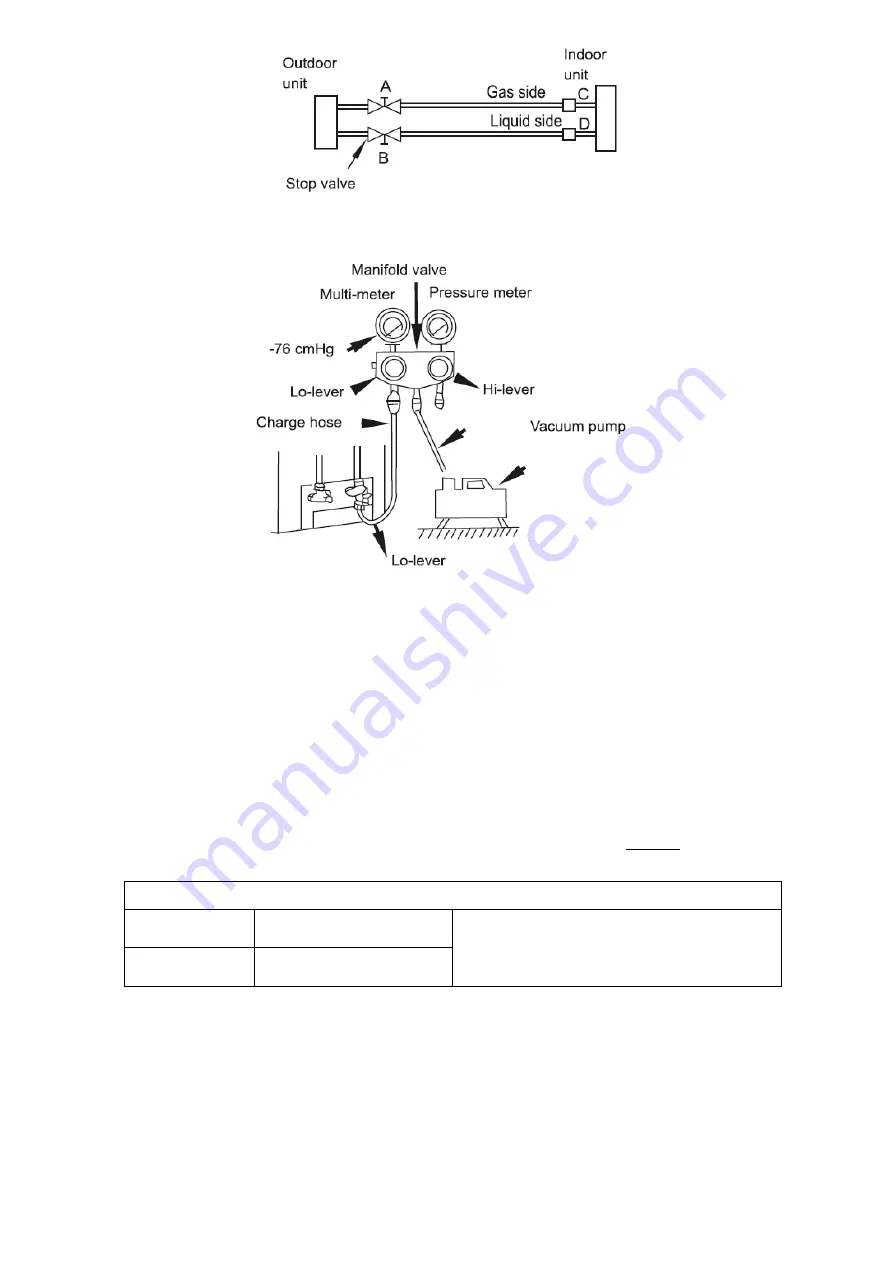

Fig. 18 – Vacuum Pump Application

6.4 Charging the system

Once all electrical connections are correctly made, the unit is ready to be commissioned. Refrigerant may only be added

after performing a leak test and system evacuation.

Start the system in cool mode and allow it to stabilise before checking liquid line sub-cooling and compressor suction

superheat. Refer to Start Up and Commissioning procedures (Section 7).

•

The system is pre-charged with R410a refrigerant for 15m actual pipe length

•

For lengths greater than 15m, additional charge is required. This is done by starting the unit and using it to

draw refrigerant (liquid only) through the compressor suction pipe Schrader valve, located in the

compressor compartment. Refer to Section 6.2.

•

Refrigerant containers should be opened slowly to avoid injury.

•

Always use protective gloves and protect your eyes when charging refrigerant.

Refrigerant Charge Adjustment

The outdoor unit is pre-charged with refrigerant for a 15 m pipe run.

Please calculate the refrigerant adjustment required according to the diameter and length of the liquid line pipe of the

indoor/outdoor connection.

System Refrigerant Adjustment

Less than 15m

REMOVE Refrigerant

OR

30g/m for Ø9.52 liquid line

More than 15m

ADD Refrigerant

60g/m for Ø12.7 liquid line

The correct measurement and assessment of superheat and sub-cooling values should be the only measures used

to confirm correct system charge

.

•

Superheat should be between 4 and 9K

•

Sub-cooling should be between 2 and 8K

•

Discharge gas temperature should not exceed 130°C in any circumstances

•

Do not overcharge.