Wheel diameter measuring gauge, IDK-BT

IDK-BT [Revision 2.2] 4

th

September 2017

13

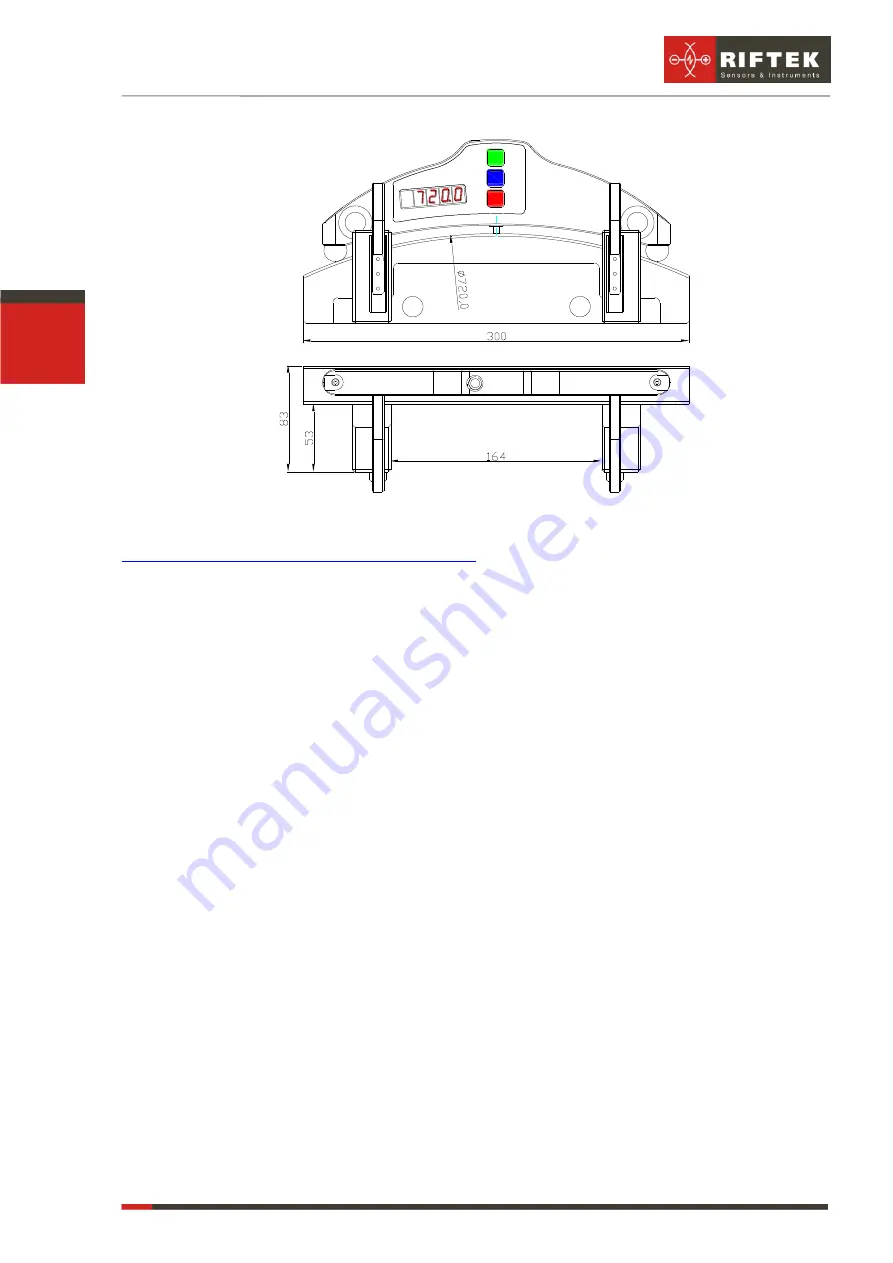

RF510.11.XXXX

Figure 5

NOTE:

Video-help for calibration procedure you can find here

www.riftek.com/resource/video/idk_calibr.avi

12. Working with the gauge and PDA

12.1. Operation principle

Operator mounts the gauge onto the wheel to be measured. Having received a

command from PDA, the gauge performs the measurement of the wheel diameter.

Measurement result is displayed on PDA, can be saved in the PDA memory, and trans-

ferred to the PC database. Simultaneously, additional parameters can be saved: opera-

tor number, side identifier (left or right wheel), axis number, locomotive (carriage) num-

ber, wheel pair number, etc.

12.2. Gauge and PDA activation

12.2.1. Gauge turn-on

Press

Red

button to turn on the power. The display shows “

ErrP

” message if the

accumulator battery voltage became lower then the control level. In this case the short-

term work is possible after pressing any key.

12.2.2. PDA turn-on

Turn the PDA on by pressing the button (1), Fig. 2. Activation indication (2) will

show a green LED lit.

After the PDA is switched on, some time will pass until automatic wireless

communication is set between the gauge and the PDA, which is accompanied by

blinking of a blue LED (1) on the diameter gauge. The LED goes out when the link is

established.

The PDA screen will show the main program window containing: main menu;

indicators of PDA charging degree; indicator of Bluetooth connection showing serial

number of the gauge with which connection is established and the

Measurement

button.