Page 9

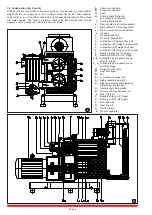

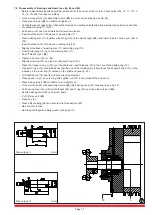

6.2 Oil Lubrication (see data sheets D 134 + D 137)

The pumps are despatched with the oil tanks (except fresh oil) filled. However

it is advisable to check the oil levels.

Sight glass: Fresh oil (I), LP-bearing (I

1

), HP-bearing (I

2

), gearbox (I

3

). If oil

level is low, please refill. Oil filling points: Fresh oil (H), LP-bearing (H

1

), HP-

bearing (H

2

), gearbox (H

3

). An oil level switch (V) is fitted in the fresh oil tank

as standard. This automatically stops the pump if the minimum oil level is

reached (depending on actual site control installation). The pump can be re-

started after refilling. We recommend the following oil brands: Bechem VBL

100, BP Energol RC 100, Esso rotary oil 100, Mobil vacuum pump oil heavy,

Shell Tellus oil C 100 or Aral Motanol HK 100. Other lubricants should only

be used after reference to the manufacturer. The bearing and gear oil should

be completely changed once a year. Under extrem conditions we recommend

earlier maintenance if necessary. Oil type plate (M), oil drain LP-stage (K

1

)

and HP-stage (K

2

). The gearbox oil should be changed after approx. 3000

operating hours (K

3

).

Recommendations for cheking the fresh oil consumption: Fill up fresh oil to

the upper level indicated on the sight glass (I). Operate machine for a period

of 10 hours. Refill fresh oil again to the upper level.

Oil consumption = Refill / 10 hr

Old and used oil must be disposed of corresponding with the

relevant health, safety and environmental laws.

If the oil brand is changed. The old oil must be drained completely from

the tank and the oil cooler.

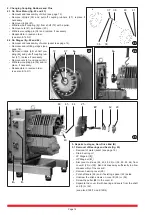

6.3 Oil metering pump

The oil metering pump is set to necessary output at the factory.

This rate can only be changed on request to our Company.

This rate can only be changed on request to our Company by turning the regulating screw. The capacity will be changed about

1

/

3

per revolution. Reduce oil counter-clockwise, increase oil clockwise.

Before first start-up of the pump, the oil flow should be primed by giving the oil pump handle approximately 150

- 200 turns. This procedure should also be carried out if the pump has been stationary for a week or more, or after

repairs to the gear unit or change of stages or after cleaning of the oil pump or the oil lines.

Oil Consumption for VWZ and VPA (VWZ + Roots booster): l / h

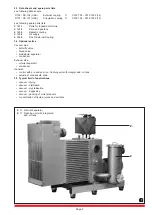

6.4 Initial Operation

Warning –> Start-up with pipework

At start-up, severe damage may occur if there is debris in

the pipework.

We therefore recommend a vacuum tight inlet filter of 5

micron rating is installed for start-up.

Start the pump momentarily to check the direction of rotation

(arrow (O

➞

D 134 + D 137)). As an option the motor coupling

can be fitted with a unidirectional free-wheel device to prevent

the vacuum pump rotating in the event of incorrect motor

rotations.

Important: When the pump is handling moist or aggressive

media, it should be run before and after the process operation

with a closed process vacuum valve, but with an open bleed

valve (optional item). This pre and post running should take 20

to 30 minutes. The pre run is to bring the pump up to operating

temperature and therefore prevent condensation of vapours

inside the pump. The post run is to purge the pump of residual

media and to leave the internals with a film of clean oil for the

period it will be stationary.

Reduction of oil

Increase of oil

Oil metering pump

VWZ

702

1002

1202

50 Hz

0.342

1.094

1.367

60 Hz

0.410

1.312

1.640

VPA

702. ...

1002. ...

1202. ...

50 Hz

0.427

2.280

2.848

60 Hz

0.513

2.736

3.417

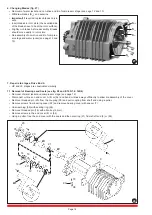

7. Maintenance

When maintaining these units and having such situ-

ations where personnel could be hurt by moving

parts or by live electrical parts the pump must be isolated

by totally disconnecting the electrical supply. It is impera-

tive that the unit cannot be re-started during the mainte-

nance operation.

Do not maintain a pump that is at its normal operating

temperature as there is a danger from hot parts or hot

lubricant.

Hazardous substances must be removed before serving.

Maintenance personnel should be informed regarding the

presence of anything harmful and also be informed about

all relevant safety regulations before carrying out any

work.

7.1 Oil Metering Pump

The lubrication oil pump requires no special attention during

operation. Care should be taken to ensure that there is always

sufficient oil in the reservoir so that air is not pumped into the

oil lines. If this should occur the oil lines must be dis-connected

and the pump hand operated to remove all air bubbles from the

lines before re-connecting.

At least once a year the oil pump should be cleaned out by

pumping petroleum through it. At the same time the oil reservoir

should be flushed out. This cleaning is also recommended if the

pump has been stored for a long time after delivery before

putting into operation as hard deposits may have formed which

could adversely affect the pump performance.